Top Suppliers Cr39 1.499/1.56/1.61/1.67/1.74/1.59 Resin Bifocal, Progressive, Blue Light Cut, Photochromic Eyeglasses Optical Lens

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Top Suppliers Cr39 1.499/1.56/1.61/1.67/1.74/1.59 Resin Bifocal, Progressive, Blue Light Cut, Photochromic Eyeglasses Optical Lens, We recognize your enquiry and it truly is our honor to work with each and every pal globally.

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for China Optical Lens and Cr39 Lens price, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

Description

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 PC | Lenses Material: | Resin |

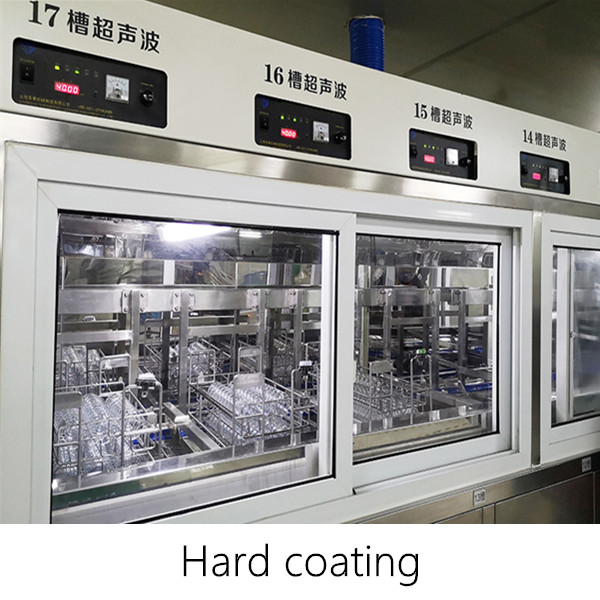

| Lenses Color: | Clear | Coating: | EMI, HMC |

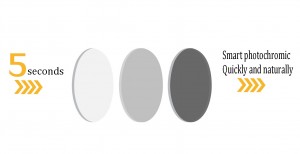

| Other Name | 1.59 PC POLYCARBONATE PHOTOCHROMIC PGX HMC | Product Name: | 1.59 PC POLYCARBONATE PHOTOCHROMIC PGX HMC |

| Material: | Acrylic | Design: | Aspheric |

| Multi color: | GREEN | Color: | Clear |

| Abrasion Resistance: | 6~8H | Transmittance: | 98~99% |

| Port: | Shanghai | HS CODE: | 90015099 |

What are polycarbonate lenses made of?

polycarbonate lens

A polycarbonate lens is made of a flexible plastic initially designed as a material for aerospace gear in the Apollo Space Shuttle expedition. Also known as poly, this lens is highly impact-resistant. It is famous for withstanding forces that typically chip or shatter other materials.

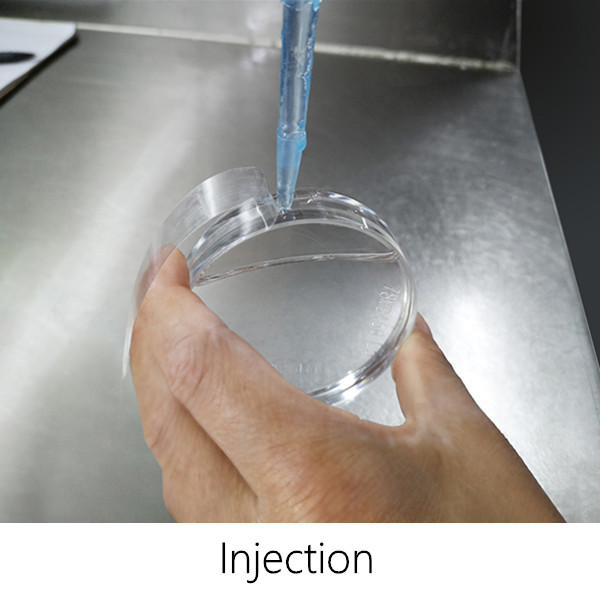

Polycarbonate is a super-strong material despite its lightweight quality. It is a thermoplastic that starts as a small and solid pellet, which undergoes injection molding. Poly is heated until it melts and is quickly poured into the lens mold. Then, it is compacted under high pressure and cooled off into the final lens form.

Advantages

Are polycarbonate lenses suitable for you?

How to Care for and Clean Polycarbonate Lenses

Detailed Images

Product Feature

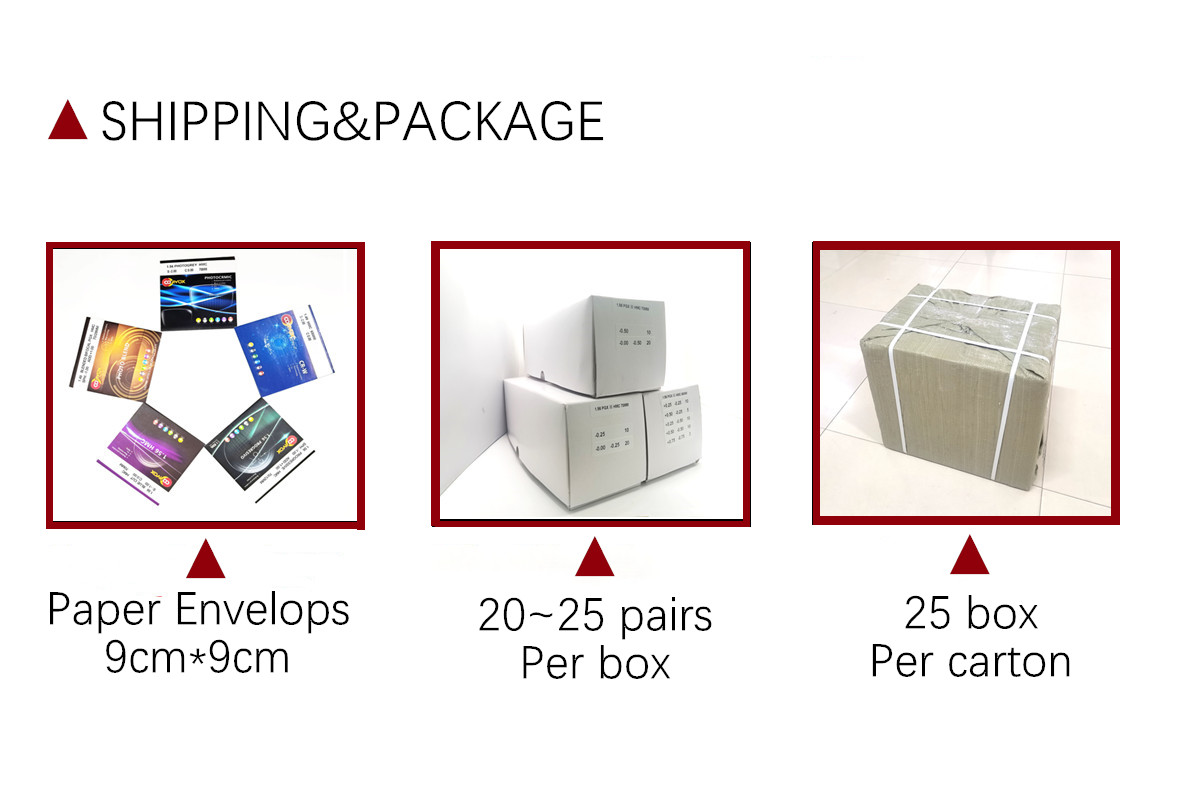

Product packaging

- Packaging Details1.56 hmc lens packing:

envelops packing (For choice):

1)standard white envelops

2)OEM with customer’s LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

Production Flow Chart

About Us

Certificate

Exhibition

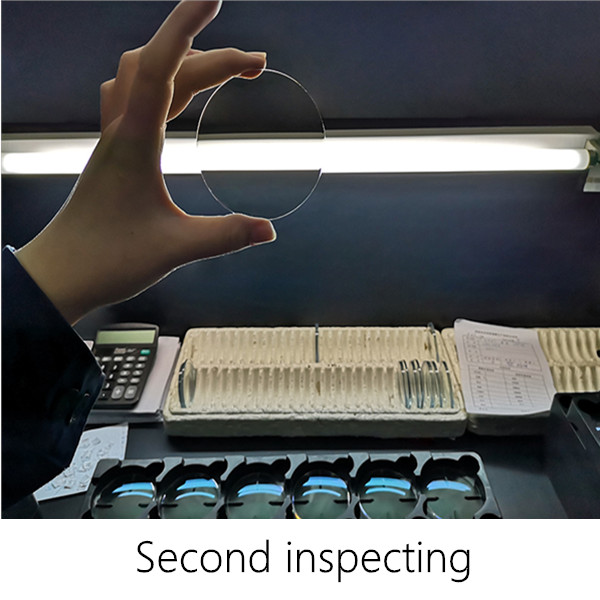

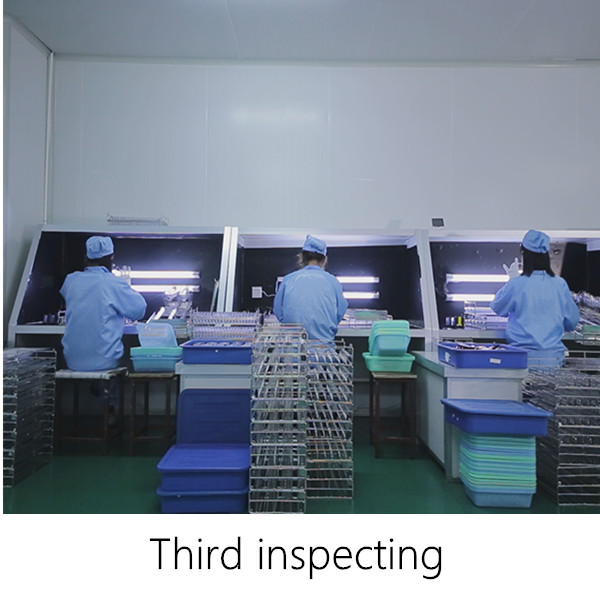

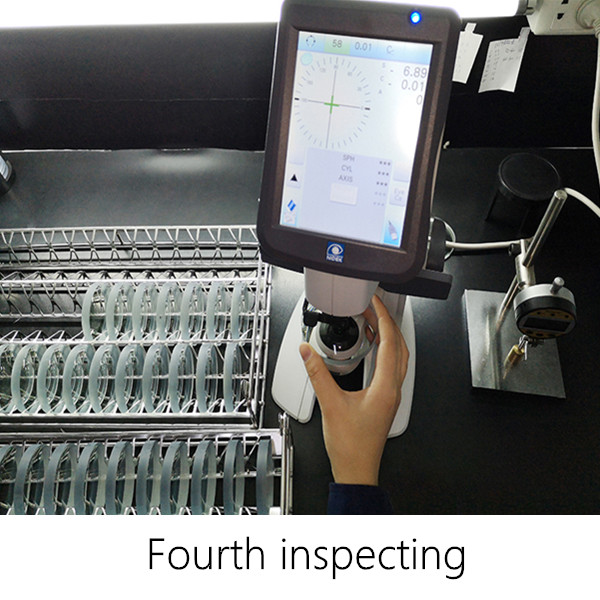

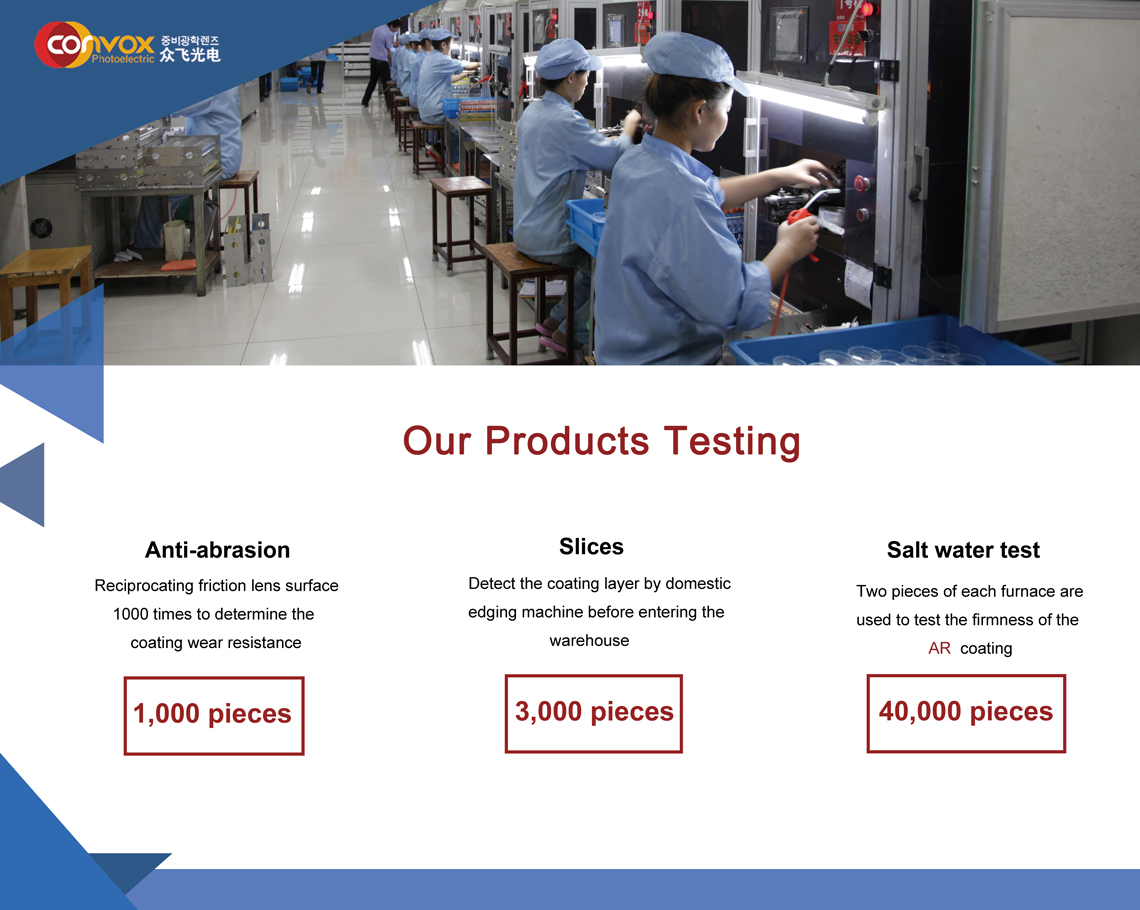

Our Products Testing

Quality Checking Procedure

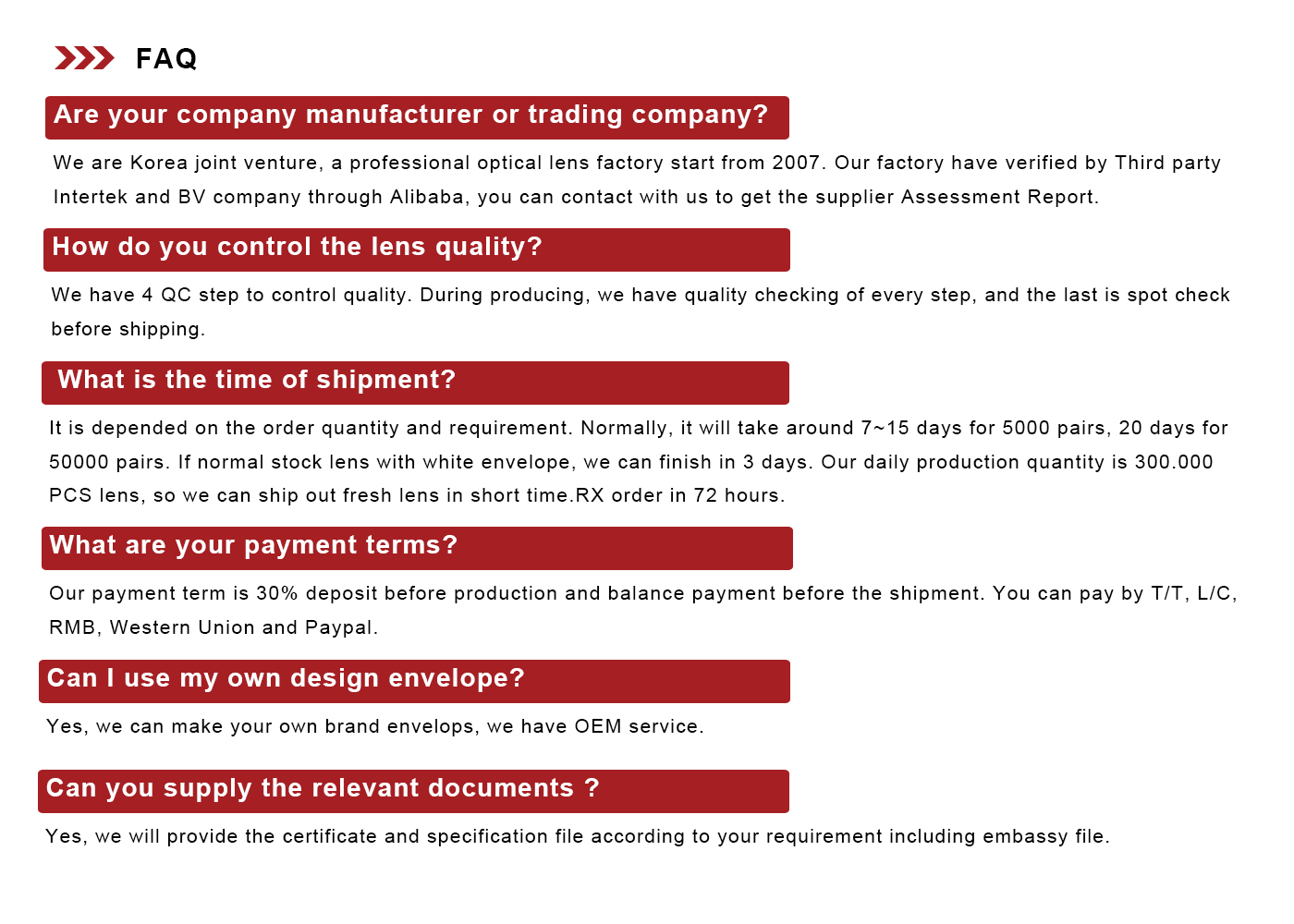

FAQ

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Top Suppliers Cr39 1.499/1.56/1.61/1.67/1.74/1.59 Resin Bifocal, Progressive, Blue Light Cut, Photochromic Eyeglasses Optical Lens, We recognize your enquiry and it truly is our honor to work with each and every pal globally.

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Top Suppliers Cr39 1.499/1.56/1.61/1.67/1.74/1.59 Resin Bifocal, Progressive, Blue Light Cut, Photochromic Eyeglasses Optical Lens, We recognize your enquiry and it truly is our honor to work with each and every pal globally.

Top Suppliers China Optical Lens and Cr39 Lens price, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!