Short Lead Time for Customized High Quality Optical Grade MGO: Linbo3 (MGO: LN) Wafer for Industries

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Short Lead Time for Customized High Quality Optical Grade MGO: Linbo3 (MGO: LN) Wafer for Industries, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for China Crystal and Optic, Our company adheres to the spirit of “lower costs, higher quality, and making more benefits for our clients”. Employing talents from the same line and adhering to the principle of “honesty, good faith, real thing and sincerity”, our company hopes to gain common development with clients from both at home and abroad!

Description

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 PC | Lenses Material: | Resin |

| Lenses Color: | Clear | Coating: | EMI, HMC |

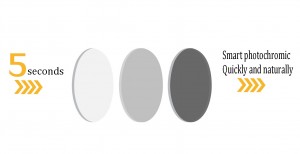

| Other Name | 1.59 PC POLYCARBONATE PHOTOCHROMIC PGX HMC | Product Name: | 1.59 PC POLYCARBONATE PHOTOCHROMIC PGX HMC |

| Material: | Acrylic | Design: | Aspheric |

| Multi color: | GREEN | Color: | Clear |

| Abrasion Resistance: | 6~8H | Transmittance: | 98~99% |

| Port: | Shanghai | HS CODE: | 90015099 |

What are polycarbonate lenses made of?

polycarbonate lens

A polycarbonate lens is made of a flexible plastic initially designed as a material for aerospace gear in the Apollo Space Shuttle expedition. Also known as poly, this lens is highly impact-resistant. It is famous for withstanding forces that typically chip or shatter other materials.

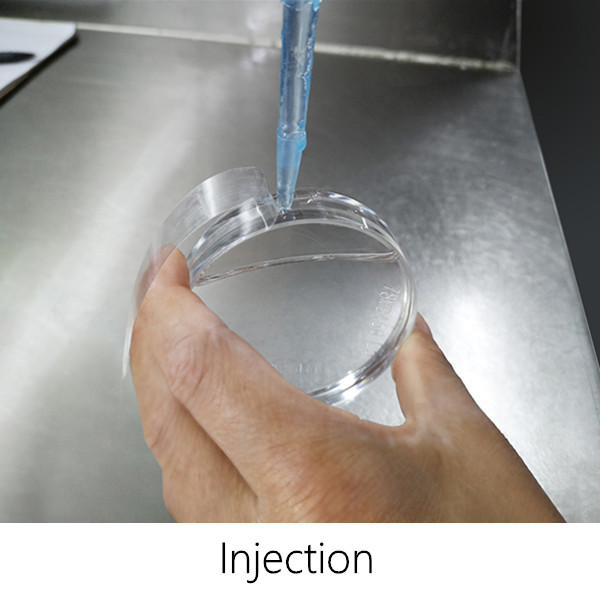

Polycarbonate is a super-strong material despite its lightweight quality. It is a thermoplastic that starts as a small and solid pellet, which undergoes injection molding. Poly is heated until it melts and is quickly poured into the lens mold. Then, it is compacted under high pressure and cooled off into the final lens form.

Advantages

Are polycarbonate lenses suitable for you?

How to Care for and Clean Polycarbonate Lenses

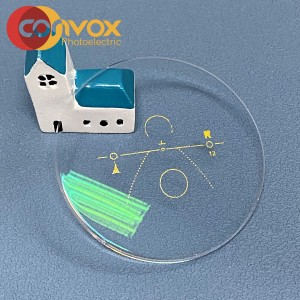

Detailed Images

Product Feature

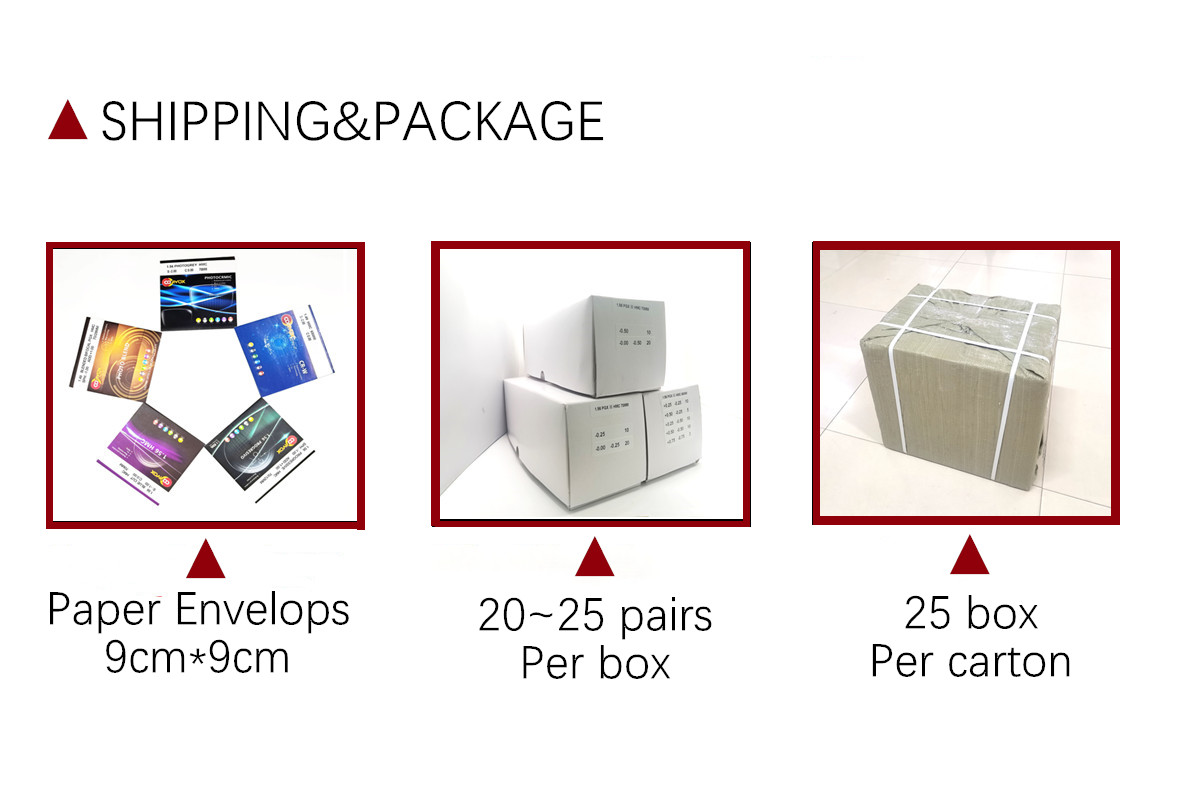

Product packaging

- Packaging Details1.56 hmc lens packing:

envelops packing (For choice):

1)standard white envelops

2)OEM with customer’s LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

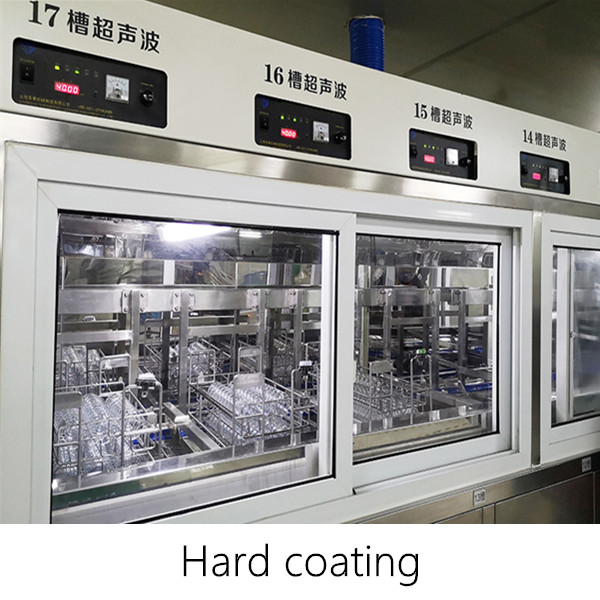

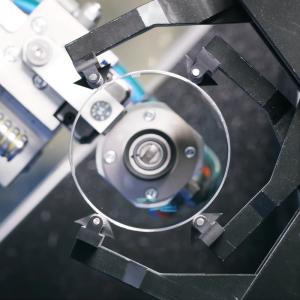

Production Flow Chart

About Us

Certificate

Exhibition

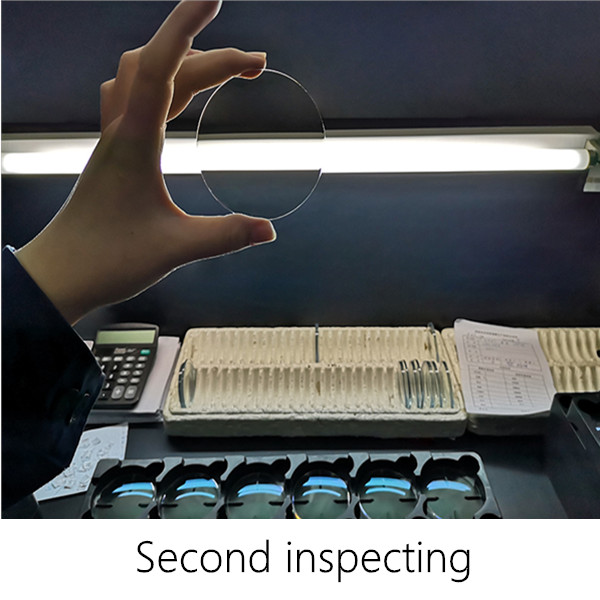

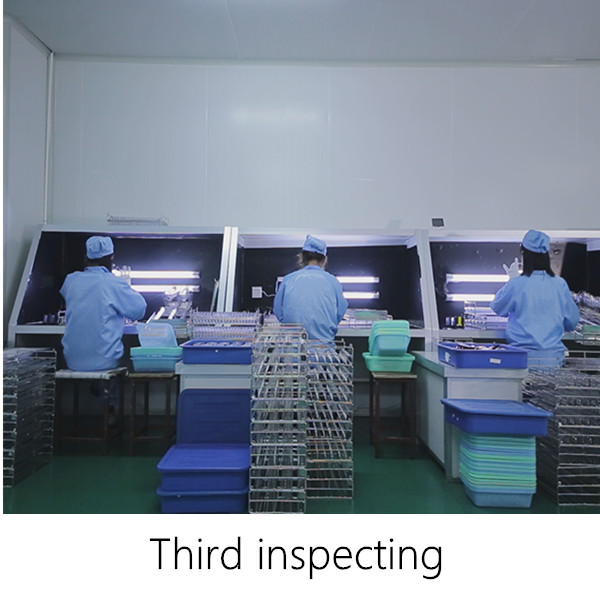

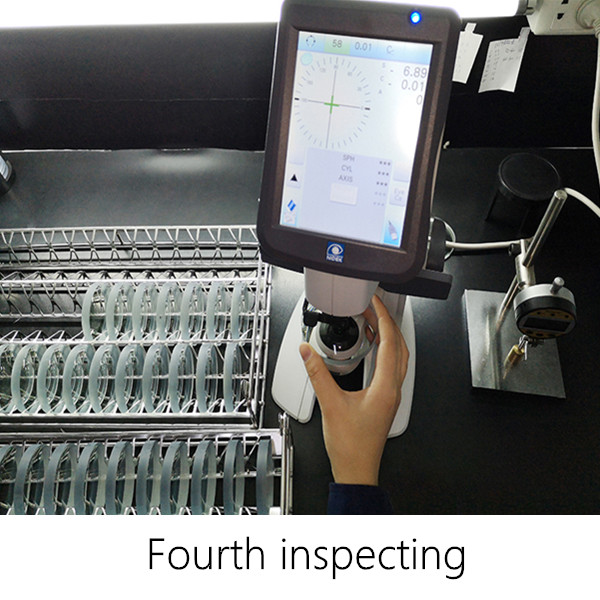

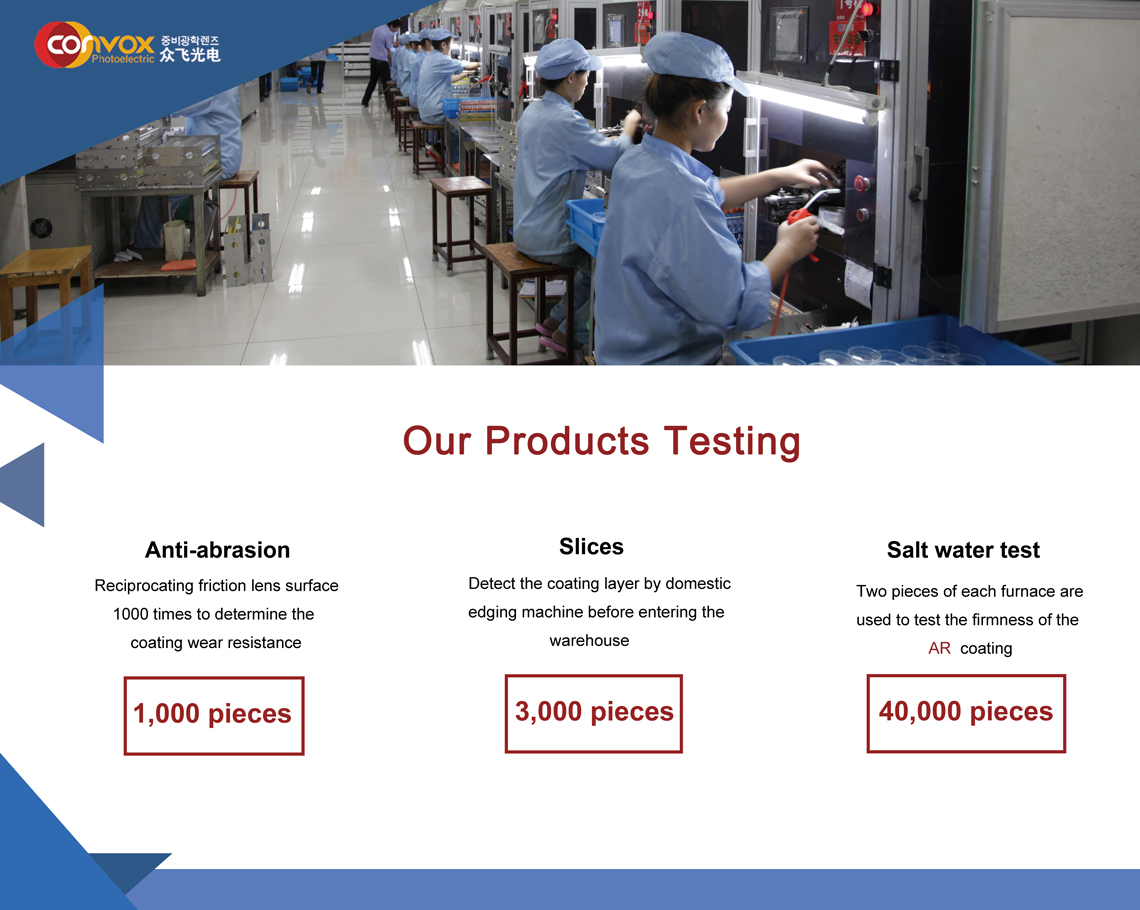

Our Products Testing

Quality Checking Procedure

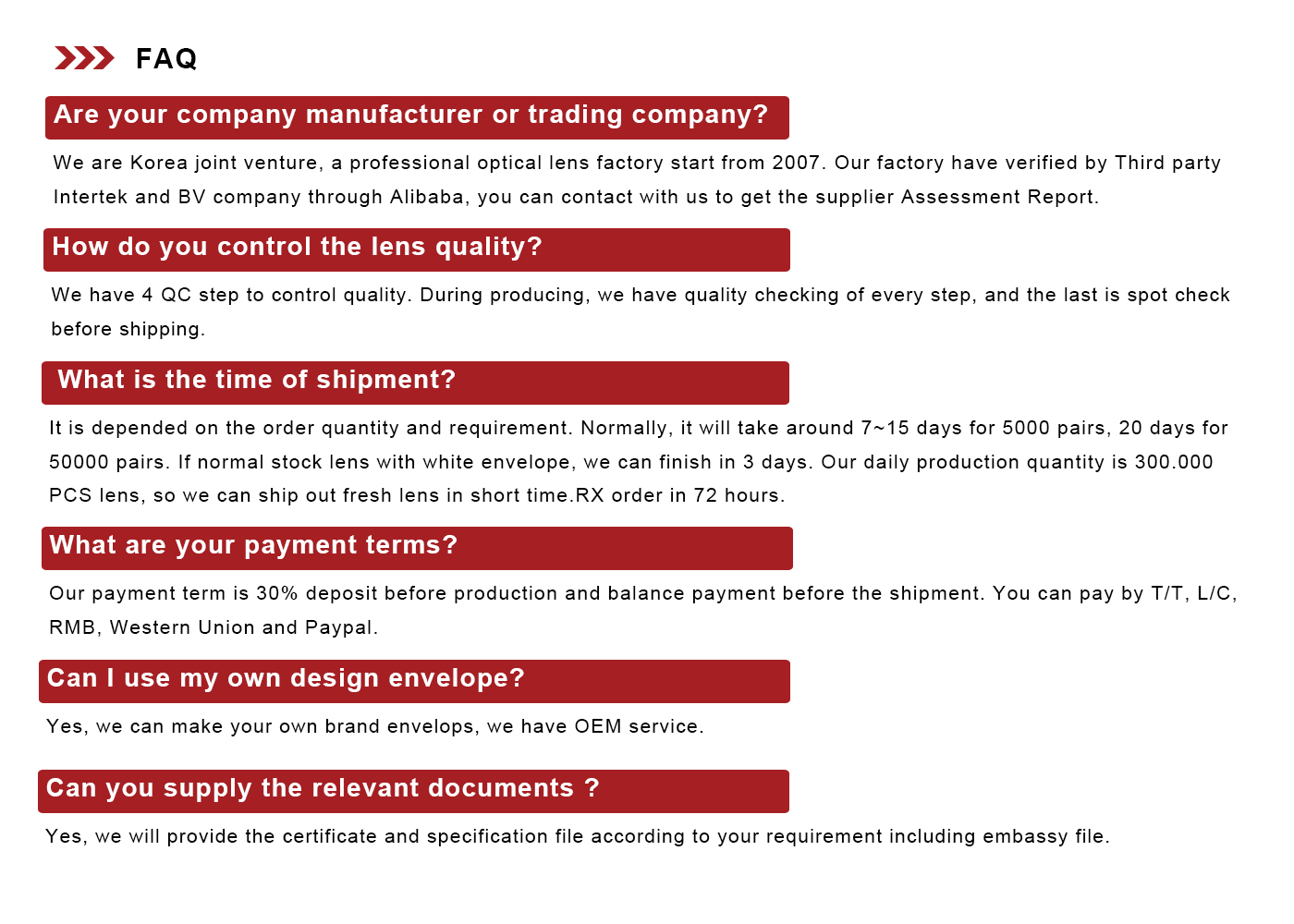

FAQ

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Short Lead Time for Customized High Quality Optical Grade MGO: Linbo3 (MGO: LN) Wafer for Industries, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Short Lead Time for Customized High Quality Optical Grade MGO: Linbo3 (MGO: LN) Wafer for Industries, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

Short Lead Time for China Crystal and Optic, Our company adheres to the spirit of “lower costs, higher quality, and making more benefits for our clients”. Employing talents from the same line and adhering to the principle of “honesty, good faith, real thing and sincerity”, our company hopes to gain common development with clients from both at home and abroad!