Semi Finished 1.56 SF Blue Block HMC UV420 Optical Lenses

What Products can we Produce?

Index: 1.499, 1.56, 1.60, 1.60 MR-8, 1.67, 1.71, 1.74, 1.59 PC Polycarbonate

1. Single Vision Lenses

2. Bifocal/Progressive lenses

3. Photochromic Lenses

4. Blue Cut Lenses

5. Sunglasses/Polarized lenses

6. Rx lenses for single vision, bifocal, freeform progressive

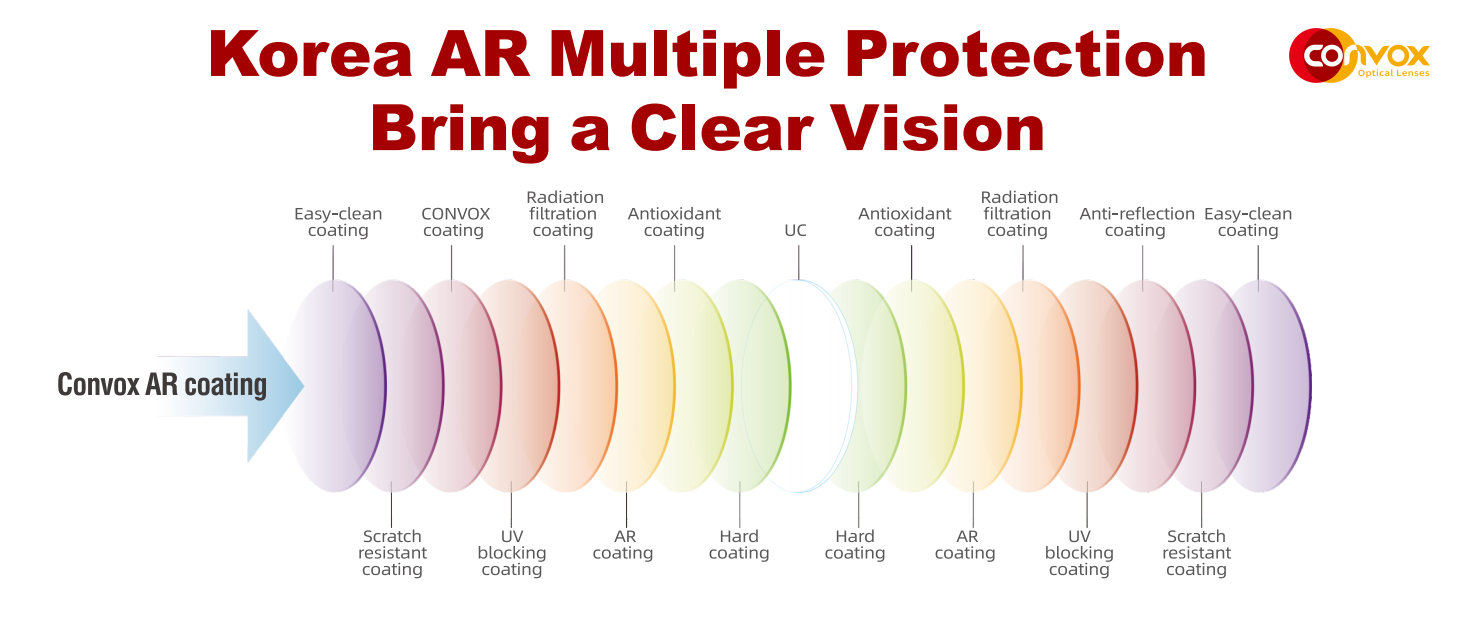

AR treatment: Anti-fog, Anti-Glare, Anti-virus, IR, AR coating color.

Product Description

| Index | 1.56 | Lenses Material: | Resin |

| Vision Effect: | Single Vision | Coating: | HMC |

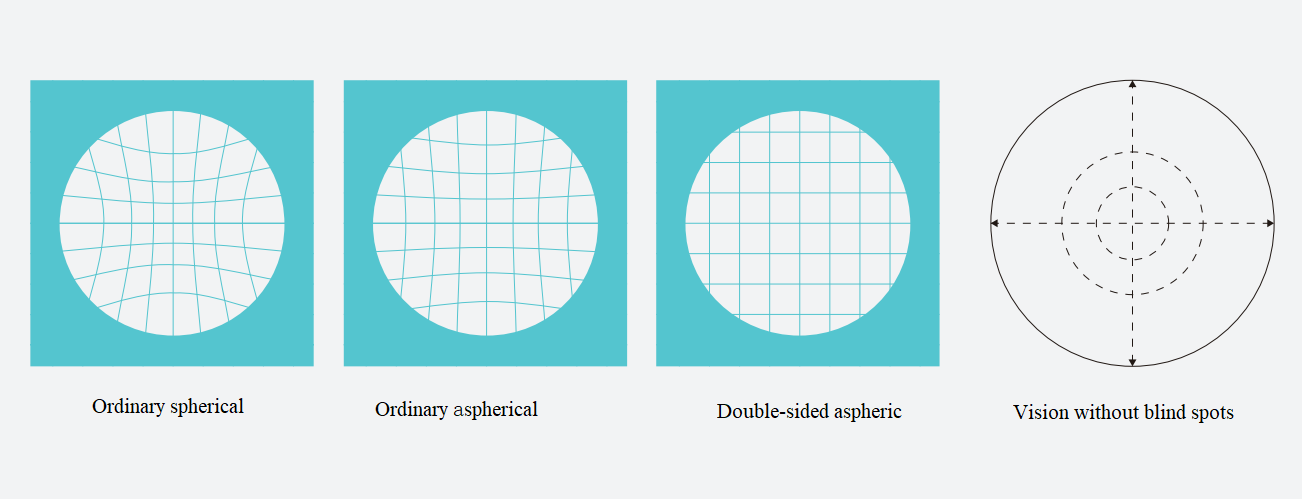

| Lenses Color: | Clear | Design: | Aspheric |

| Coating Color: | Green/Blue | Lens Color: | Clear |

| Abrasion Resistance: | 6~8H | Transmittance: | 98~99% |

| ABBE: | 36.8 | UV Value: | 420 |

| BASE Curves: | 0~-10.00 | Diameter: | 70/75mm |

Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient's prescription. Different prescription powers request for different semi-finished lens types or base curves.

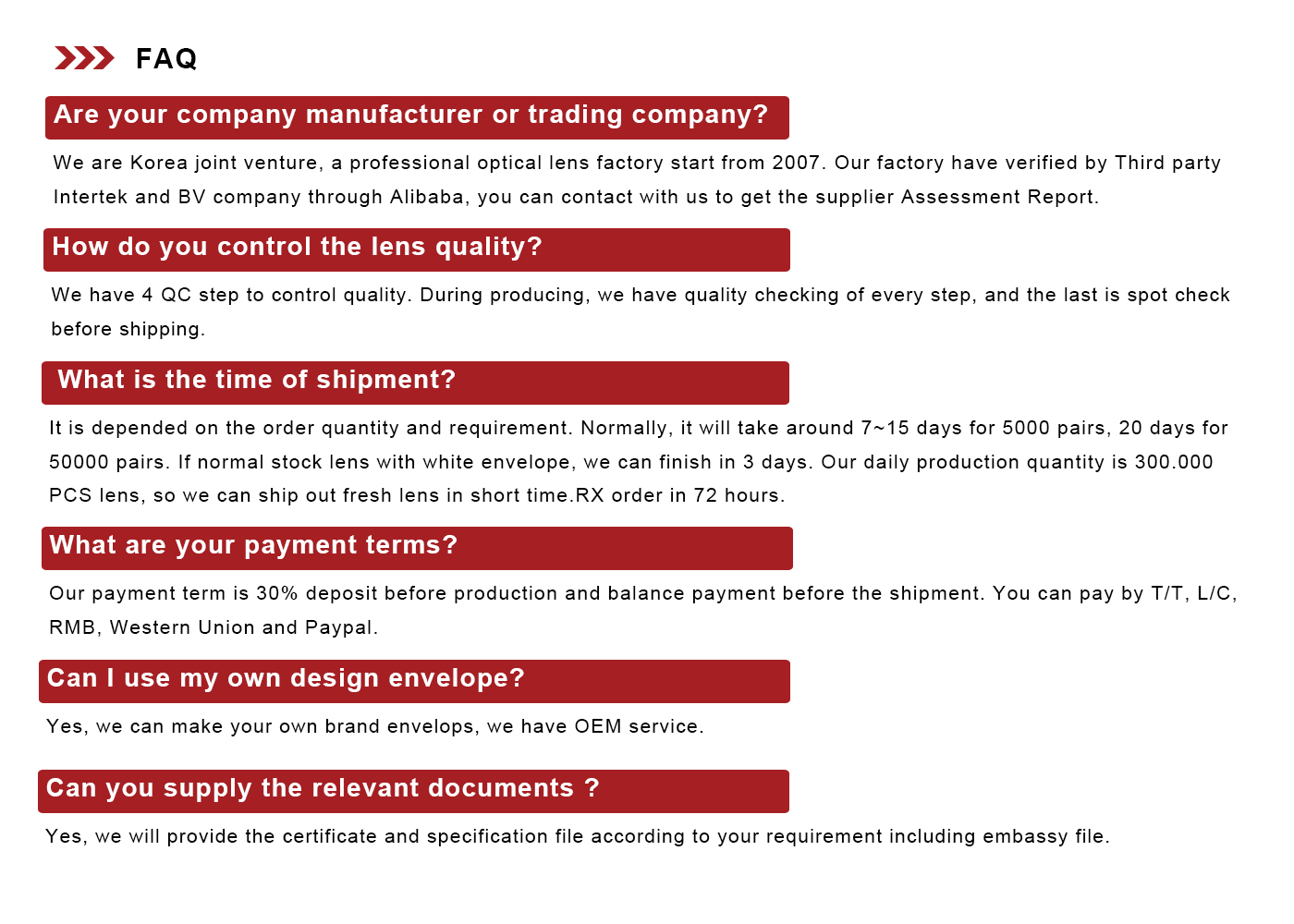

The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or "curing" of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

Why Choose Convox Semi-finished Lenses?

--High qualified rate of power accuracy and stablity after RX production.

--High qualified rate of cosmetic quality after RX production.

--Precise and consistent parameters(Base curves, Radius, Sag, etc)

Product Feature

Where is Blue Light in life?

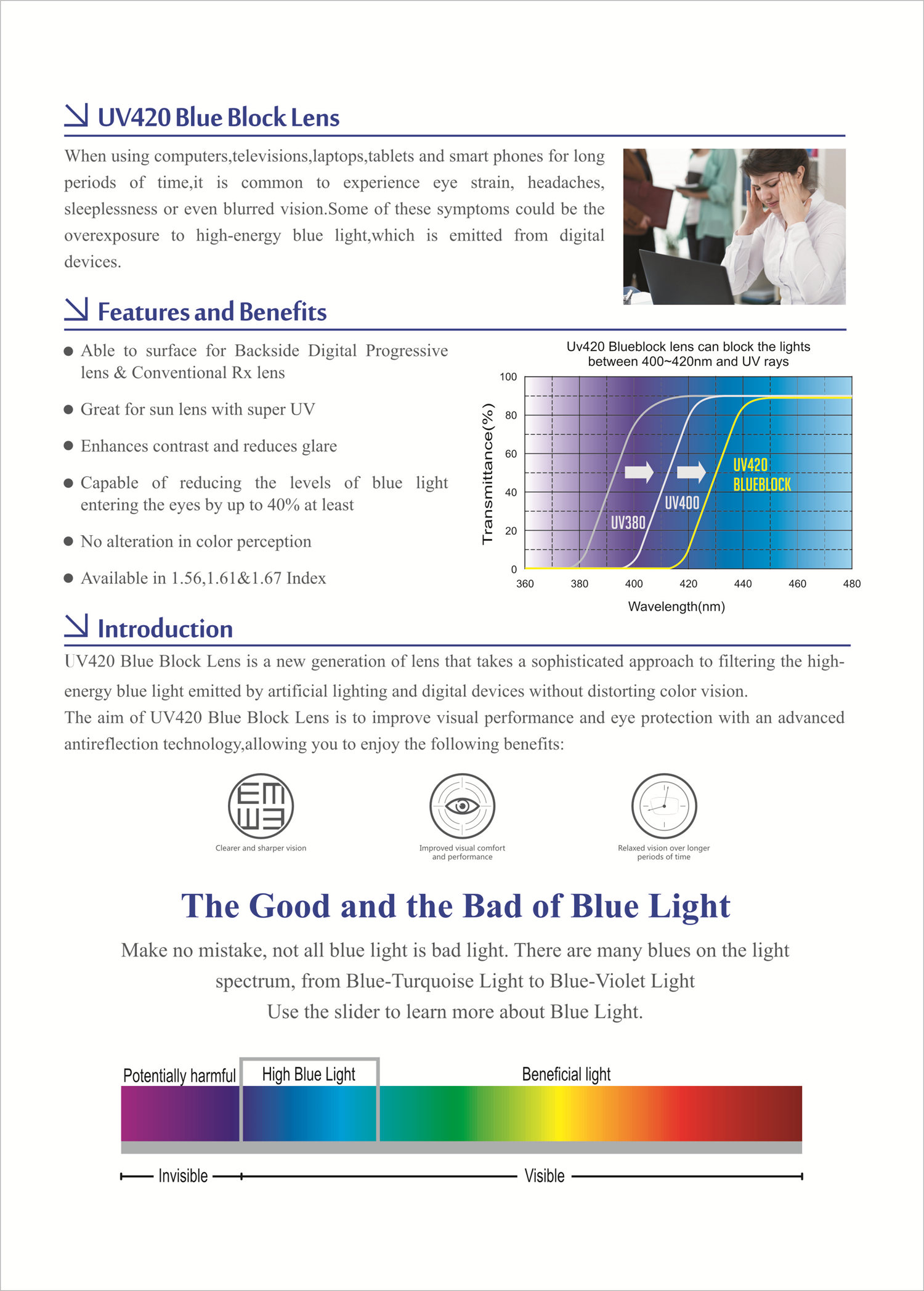

As laptops, tablets and smartphones have become more and more integrated into our daily lives, it makes sense to be aware of any potential negative effects they might have on our health. You’ve likely heard the term ‘blue light’ being bandied about, with suggestions it contributes to all kinds of nasties: from headaches and eye strain to straight-up insomnia.

Why we need blue block lens?

UV420 Blue Block Lens is a new generation of lens that takes a sophisticated approach to filtering the high-energy blue light emitted by artificial lighting and digital devices without distorting color vision.

The aim of UV420 Blue Block Lens is to improve visual performance and eye protection with an advanced anti-reflection technology, allowing you to enjoy the following benefits:

Detailed Images

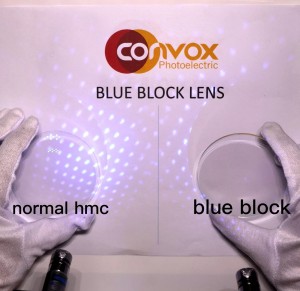

What Blue Block Lenses by Convox Actually Do?

Convox Coating

Single Vision Resin Lens

--Clear and Comfortable Vision, wide field of view.

--Using Korea Vacuum coating technology, the lens has the best optical performance of high light transmission and anti-reflection.

--Advanced technology makes the lens thinner, lighter and more beautiful to wear.

--Layer-by-layer test and inspection, the lens wear resistance and anti-fouling performance are super better.

Packaging & Delivery

Packaging Details

Semi Finish Lens Packing:

Envelops packing (For choice):

1)standard white envelops

2)OEM with customer's LOGO, have MOQ requirement

Cartons:

Standard cartons:50CM*45CM*33CM(Every carton can include around 210 pairs lens,21KG/CARTON)

Port Shanghai

Production Flow Chart

About Us

Certificate

Exhibition

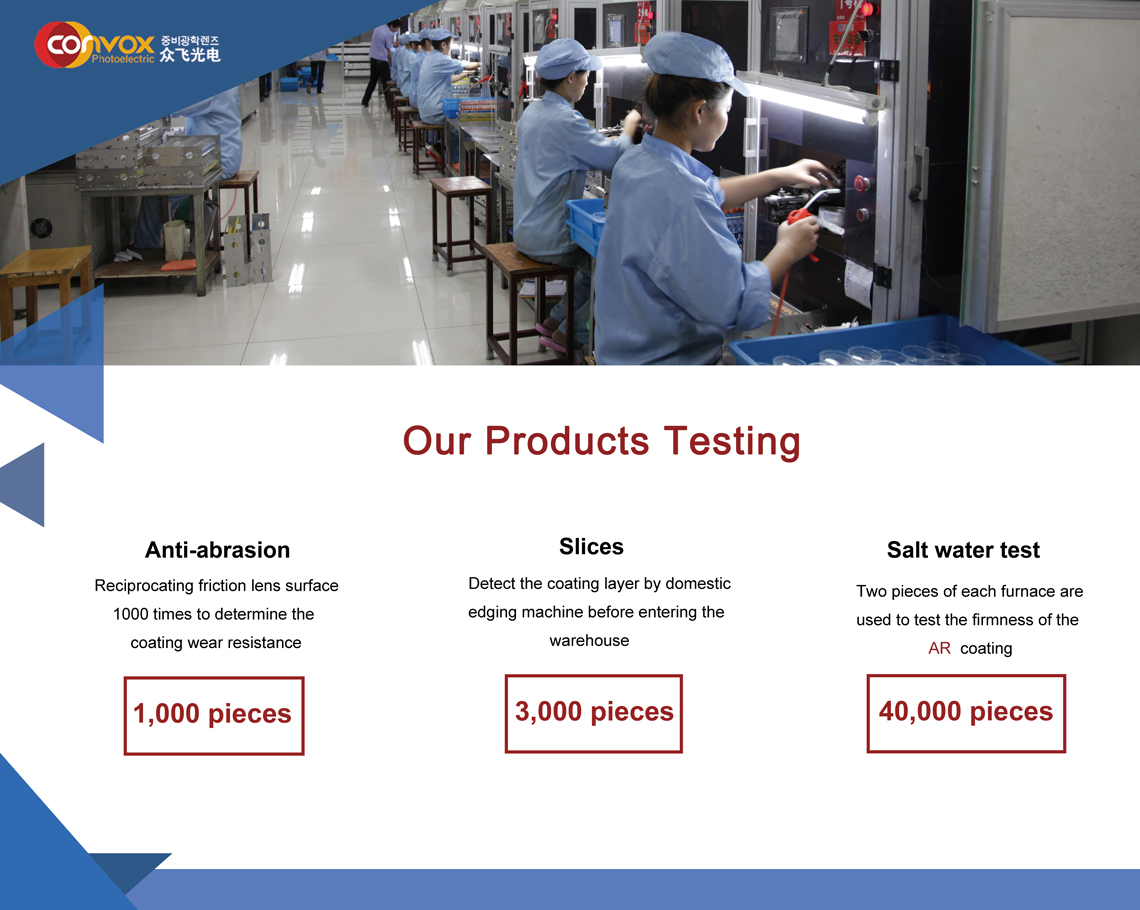

Our Products Testing

Quality Checking Procedure

FAQ