1.59 PC Polycarbonate HCT Hard Coating Tintable Optical Lens

What Products can we Produce?

Index: 1.499, 1.56,1.60, 1.67, 1.71,1.74, 1.76,1.59 PC Polycarbonate

1.Single Vision Lenses

2. Bifocal/Progressive lenses

3. Photochromic Lenses

4. Blue Cut Lenses

5. Sunglasses/Polarized lenses

6. Rx lenses for single vision, bifocal, freeform progressive

AR treatment: Anti-fog, Anti-Glare, Anti-virus, IR, AR coating color.

Quick Details

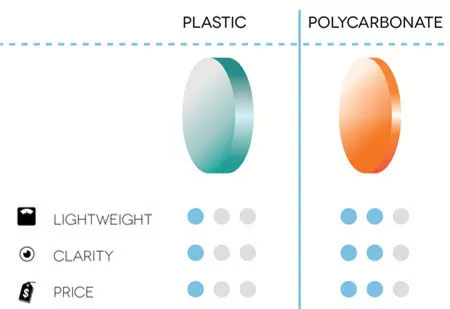

What are the advantages and disadvantages of polycarbonate spectacle lenses?

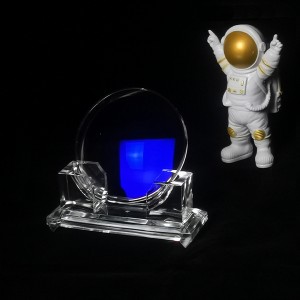

Polycarbonate lenses are made by injection moulding. These lenses have good impact resistance and therefore are ideal for children, sports and industrial purposes. It also has good UV protection and a higher refractive index than CR39.

The disadvantages of polycarbonate lenses include the fact that their abrasion resistance is poor, but when an anti scratch coating is added to this the impact resistance is reduced slightly. These types of lenses cannot be tinted easily.

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 PC | Lenses Material: | Resin |

| Vision Effect: | Photochromic | Coating: | EMI, HMC |

| Lenses Color: | Clear | Product Name: | 1.59 PC POLYCARBONATE HCT |

| Other Name | 1.59 PC POLYCARBONATE HCT | Design: | Aspheric |

| Material: | Acrylic | Color: | Clear |

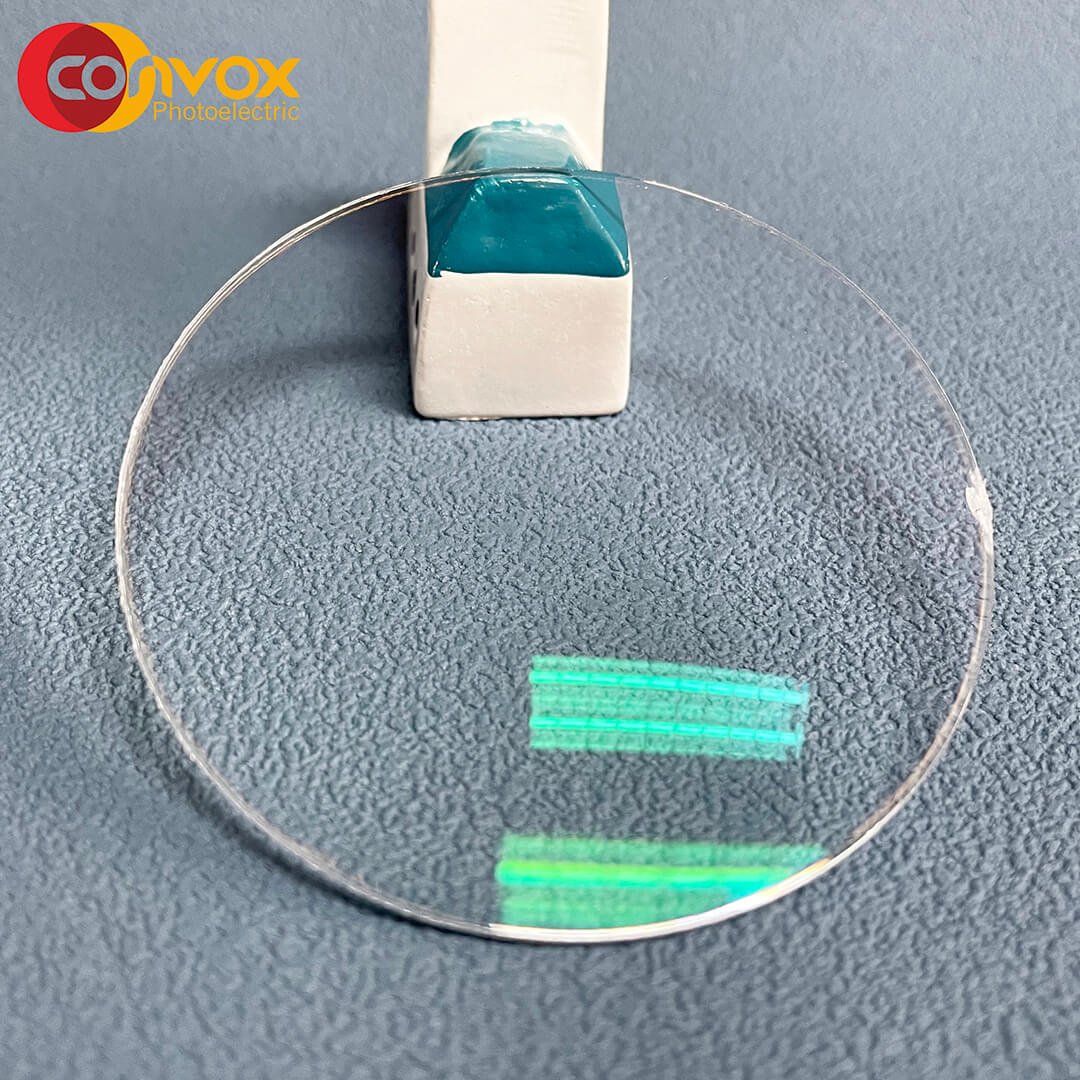

| Multi color: | GREEN | Transmittance: | 98~99% |

| Abrasion Resistance: | 6~8H | HS CODE: | 90015099 |

| Port: | Shanghai |

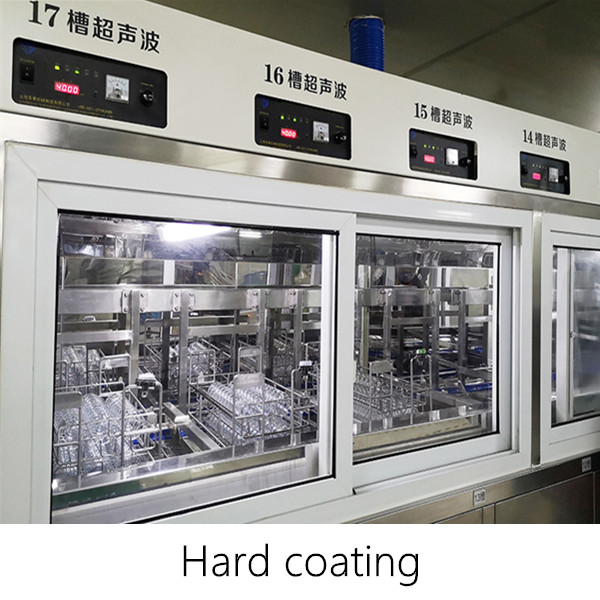

Production Flow Chart

Feature

● Polycarbonate lens is a good choice if you play sports, work where your eyeglasses could easily get damaged because it's highly resistant to impact.

● Also it is a good protection for children who are tough on their specs.

● It's lighter than glass lens, making it more comfortable to wear for long periods of time.

More

----Hardness: One of the best quality in hardness and toughness, high impact resistance.

----Transmittance:One of the highest transmittance as compared with other index lenses.

----ABBE: One of the highest ABBE value providing the most comfortable visual experience.

----Consistency: One of the most reliable and consistent lens product physically and optically.

Description

Polycarbonate was developed in the 1970s for aerospace applications, and is currently used for the helmet visors of astronauts and for space shuttle windshields. Eyeglass lenses made of polycarbonate were introduced in the early 1980s in response to a demand for lightweight, impact-resistant lenses.

Since then, polycarbonate lenses have become the standard for safety glasses, sports goggles and children's eyewear. Because they are less likely to fracture than regular plastic lenses, polycarbonate lenses also are a good choice for rimless eyewear designs where the lenses are attached to the frame components with drill mountings.

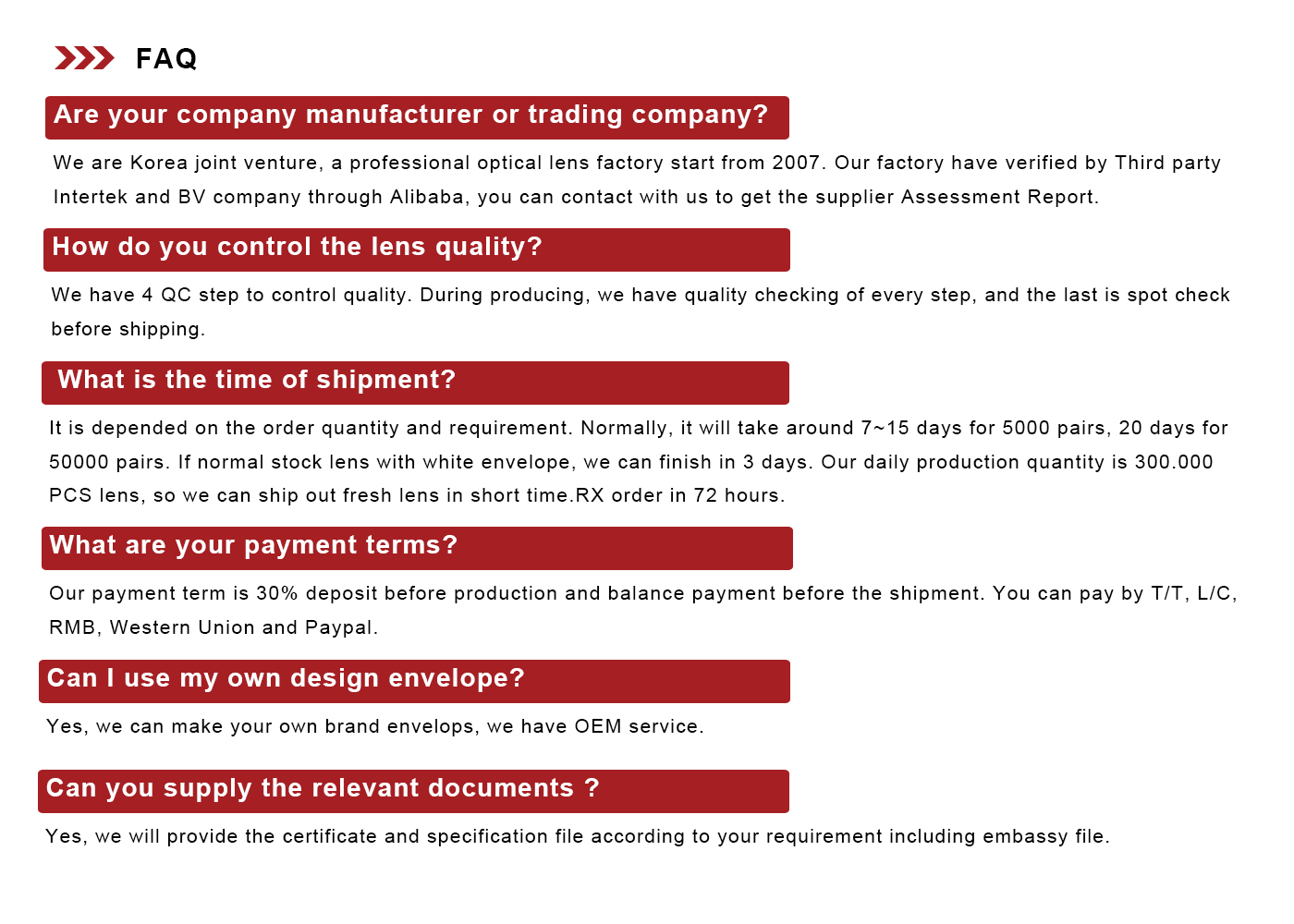

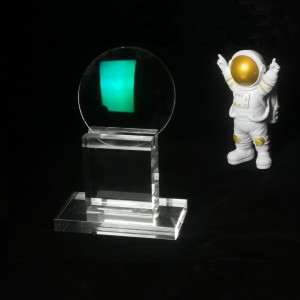

Products Show

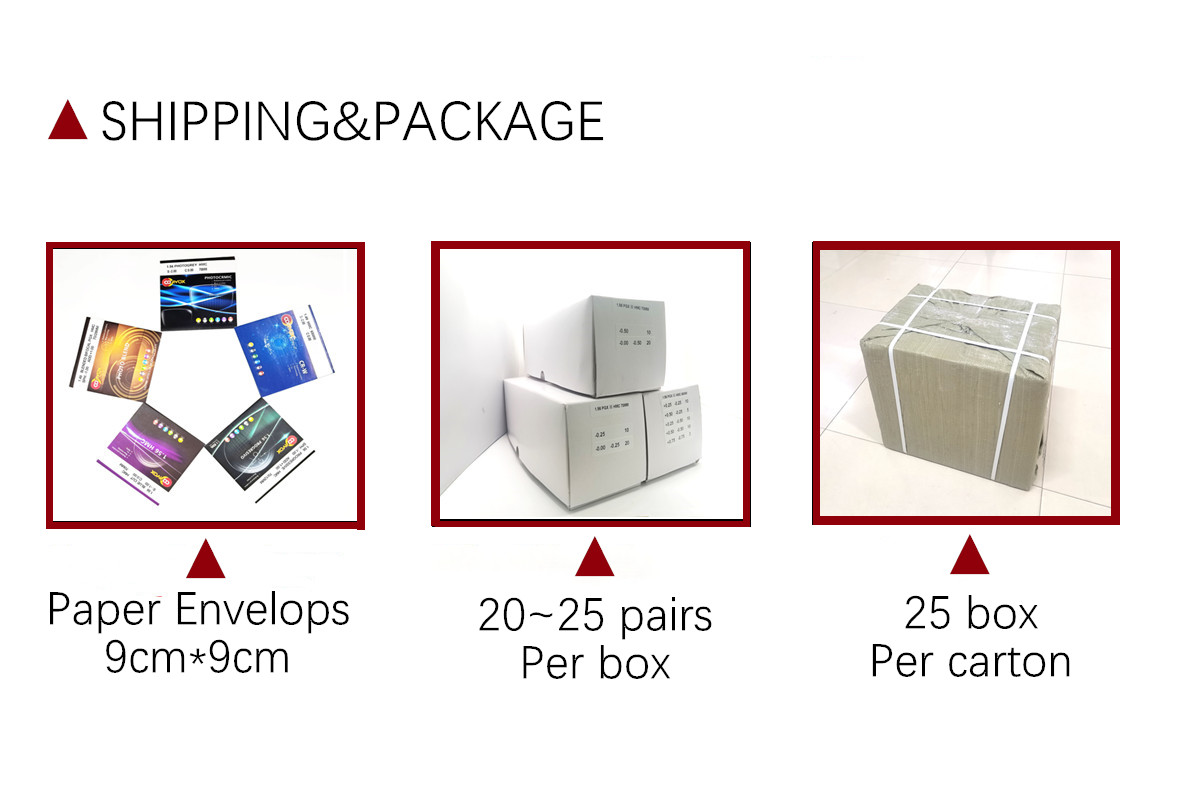

Product Packaging

- Packaging Details

1.56 hmc lens packing:

envelops packing (For choice):

1)standard white envelops

2)OEM with customer's LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

Production Flow Chart

About Us

Certificate

Exhibition

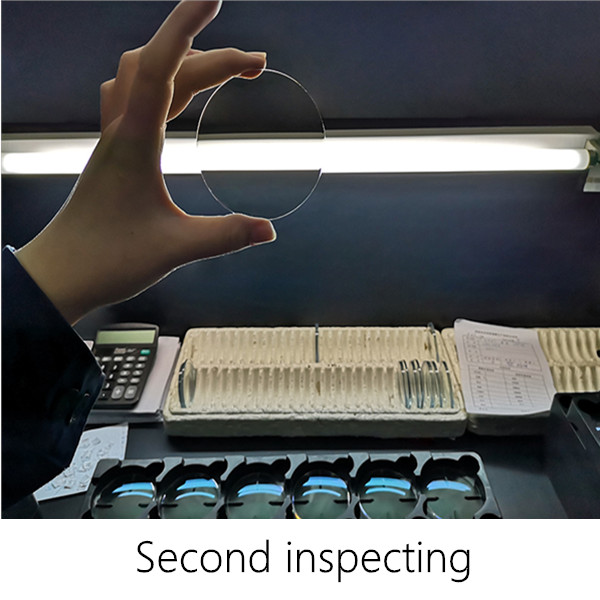

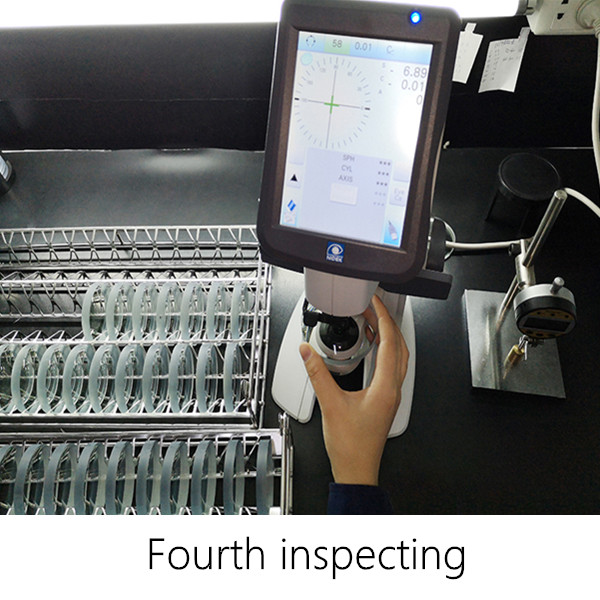

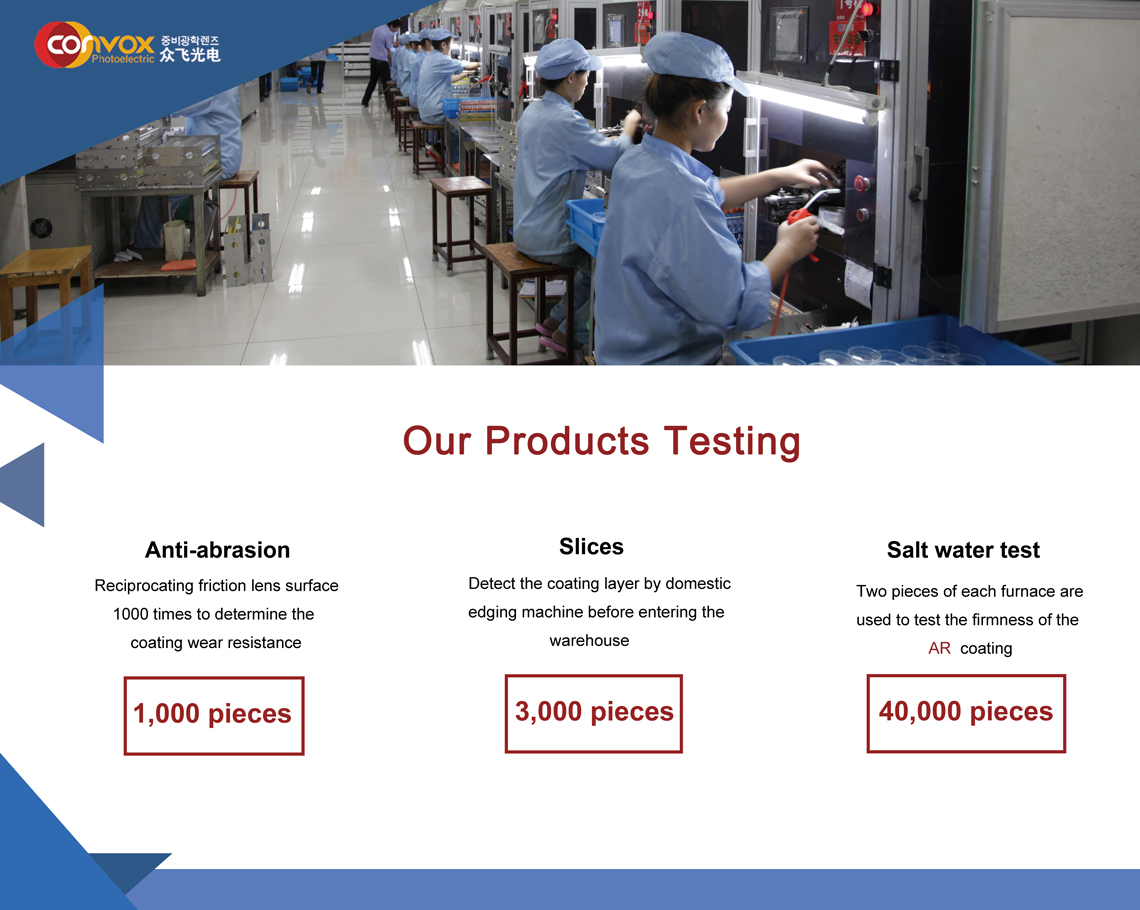

Our Products Testing

Quality Checking Procedure

FAQ