1.59 polycarbonate hmc PC optical lens

Description

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 PC | Lenses Material: | Resin |

| Lenses Color: | Clear | Coating: | EMI, HMC |

| Other Name | 1.59 PC POLYCARBONATE HMC | Product Name: | 1.59 PC POLYCARBONATE HMC |

| Material: | Acrylic | Design: | Aspheric |

| Multi color: | GREEN | Color: | Clear |

| Abrasion Resistance: | 6~8H | Transmittance: | 98~99% |

| Port: | Shanghai | HS CODE: | 90015099 |

What are polycarbonate lenses made of?

polycarbonate lens

A polycarbonate lens is made of a flexible plastic initially designed as a material for aerospace gear in the Apollo Space Shuttle expedition. Also known as poly, this lens is highly impact-resistant. It is famous for withstanding forces that typically chip or shatter other materials.

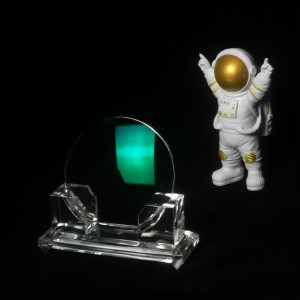

Polycarbonate is a super-strong material despite its lightweight quality. It is a thermoplastic that starts as a small and solid pellet, which undergoes injection molding. Poly is heated until it melts and is quickly poured into the lens mold. Then, it is compacted under high pressure and cooled off into the final lens form.

Advantages

Advantage

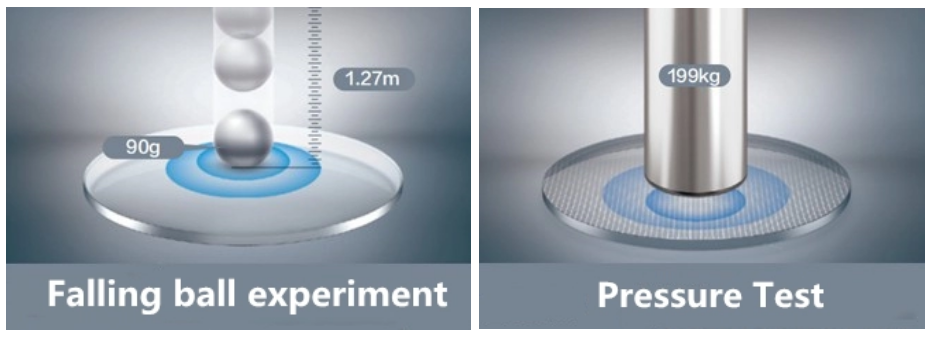

1.Impact Resistance

Polycarbonate lenses have consistently proven to be one of the most impact-resistant lenses on the market. They’re not likely to crack, chip, or shatter if they’re dropped or hit with something.

2.Thin, Lightweight, Comfortable Design

Polycarbonate lenses combine excellent vision correction with a thin profile—up to 30% thinner than standard plastic or glass lenses.

Unlike some thicker lenses, polycarbonate lenses can accommodate strong prescriptions without adding too much bulk. Their lightness also helps them rest easily and comfortably on your face.

3.Versatility

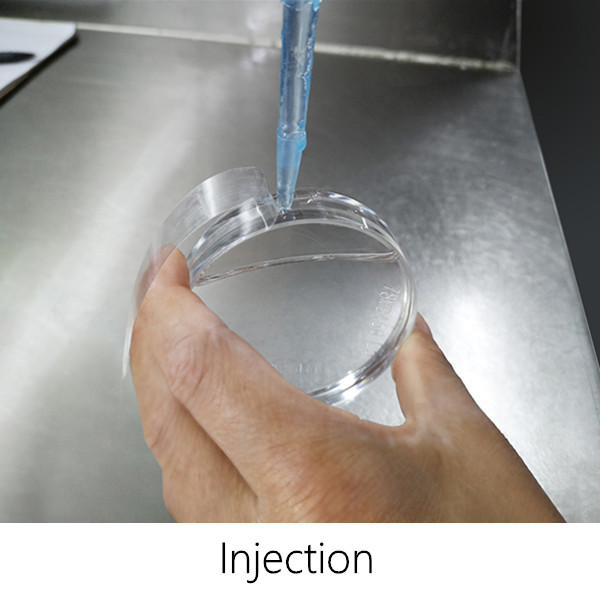

You can add a variety of different coatings and treatments to polycarbonate lenses, including anti-reflective coatings and blue-light-filtering coatings. Polycarbonate lenses can also be progressive lenses, which feature multiple zones of vision correction.

4.UV Protection

Polycarbonate lenses are ready to shield your eyes from UVA and UVB rays straight out of the gate: They have built-in UV protection, no additional treatments needed.

Are polycarbonate lenses suitable for you?

PC LENS

The doctors often suggest getting a polycarbonate-made lens for children and adults who live an active lifestyle. It is also recommended for people with reduced or no vision in one of their eyes because of the ultimate protection it grants to the wearer.

If you are doing fieldwork and are constantly exposed to hazards, you can benefit greatly from wearing a polycarbonate lens. It’s one of the best materials for safety eyewear because of its durability and impact resistance.

Polycarbonate lenses are a great steal since they offer a significant upgrade from traditional eyewear!

How to Care for and Clean Polycarbonate Lenses

CARE FOR AND CLEAN

You can care for your polycarbonate lenses the same way as you would any plastic lens: Try not to drop, damage, or scratch them, and store your frames in a glasses case when they’re not in use.

Cleaning your polycarbonate lenses can be accomplished with a dollop of dish soap, water, and a microfiber cloth. Make sure the dish soap you use is lotion-free, and follow our other tips on how to clean your glasses.

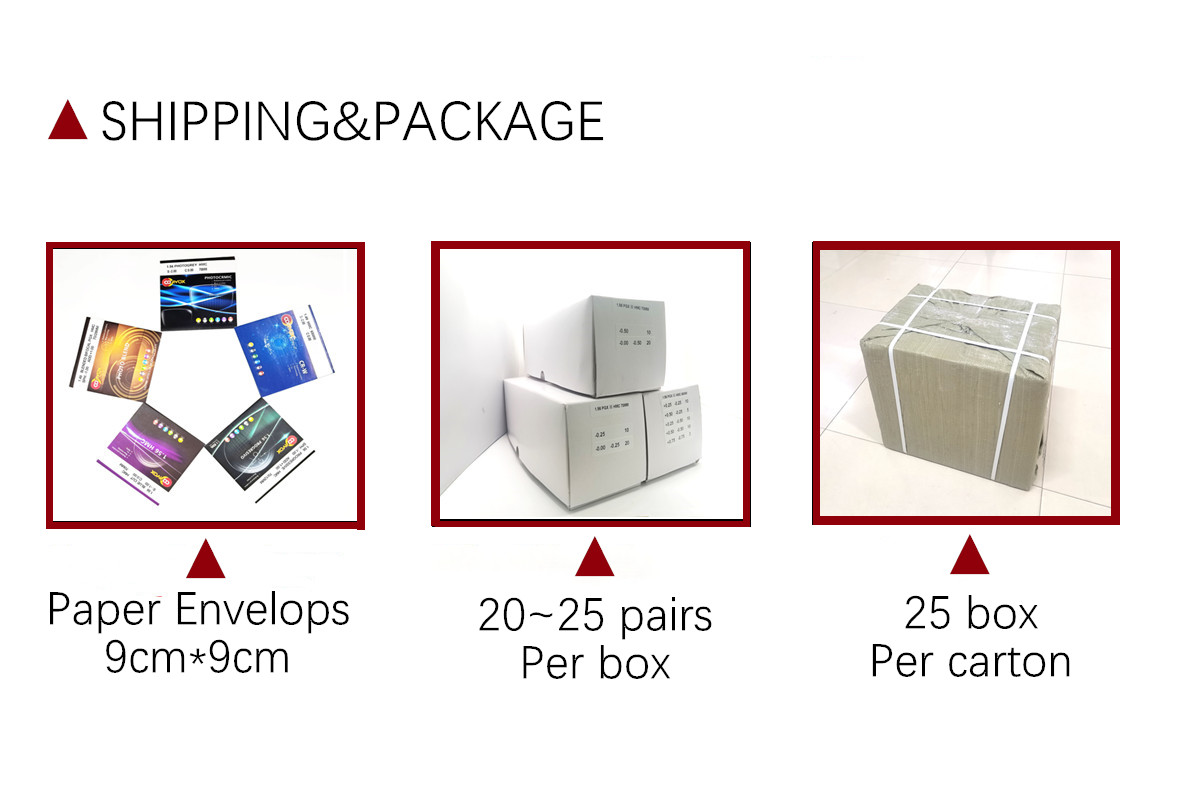

Product packaging

- Packaging Details

- 1.59 hmc lens packing:envelops packing (For choice): 1)standard white envelops

2)OEM with customer's LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

Production Flow Chart

About Us

Certificate

Exhibition

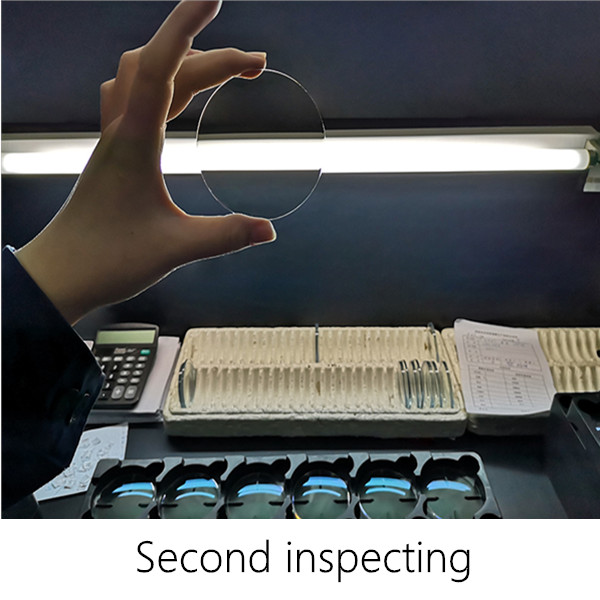

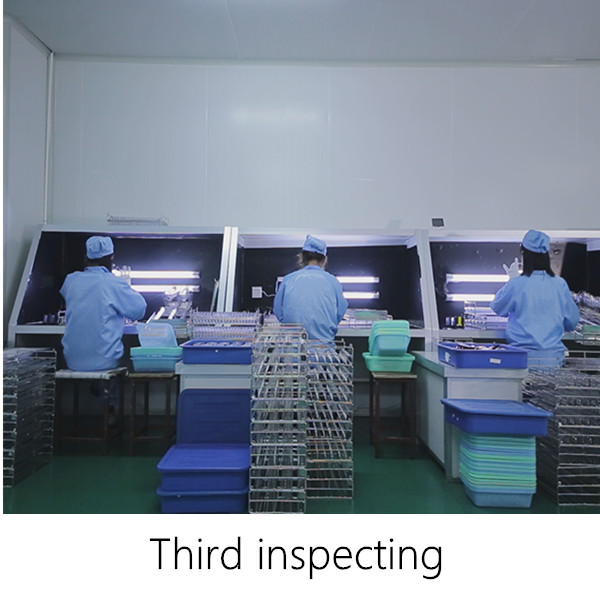

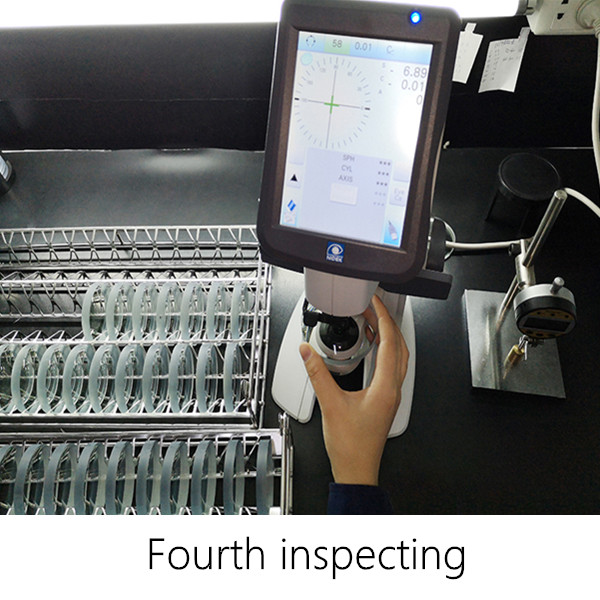

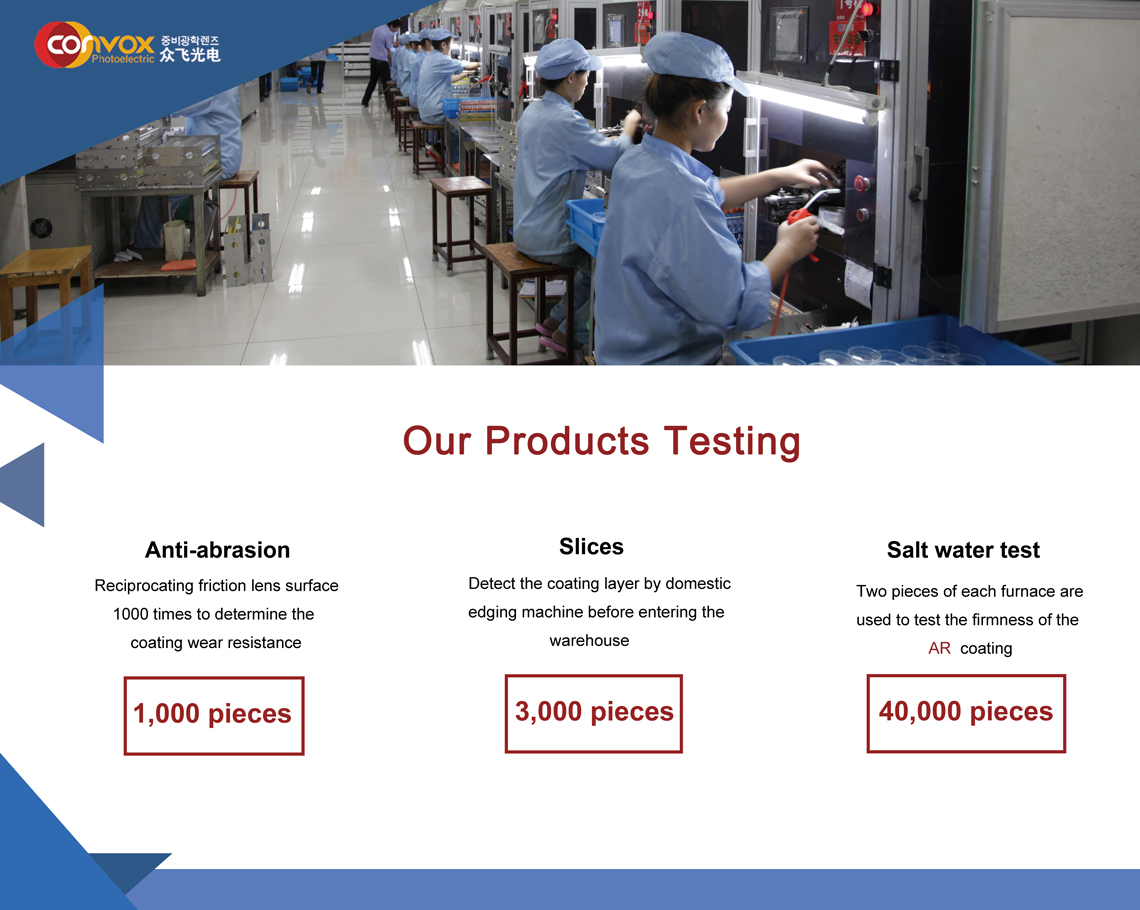

Our Products Testing

Quality Checking Procedure

FAQ