1.59 PC Progressive HMC optical lens

Products Description

| Index | 1.59 | Diameter | 75 MM |

| Monomer | 75 MM | Monomer | Polycarbonate |

| Corridor Length | 28 | Abbe Value | 37.5 |

| Specific Gravity | 1.28 | Transmission | >98% |

| Power Range | SPH: 0.00~+2.00, ADD: ADD+1.00~+3.00 | ||

1. Advantages of Polycarbonate Lenses

♦ Polycarbonate lenses are more durable than regular plastic, very lightweight.shatter-proof.

♦ Polycarbonate lenses are also shatter-proof, have the best impact resistance of any lens material. Many eye doctors choose to use only polycarbonate lenses for children's glasses. Since the lenses are shatter-proof, a child's eyes won't be damaged by shards of flying glass or plastic if the glasses are hit hard by a ball or a bat.

♦ They also have built-in ultraviolet (UV) protection to protect the eyes from the sun's harmful rays.

♦ Safety sports frames are made to hold up to high impact from fast-moving balls or heavy racquets. Polycarbonate will reduce injury from the frames themselves.

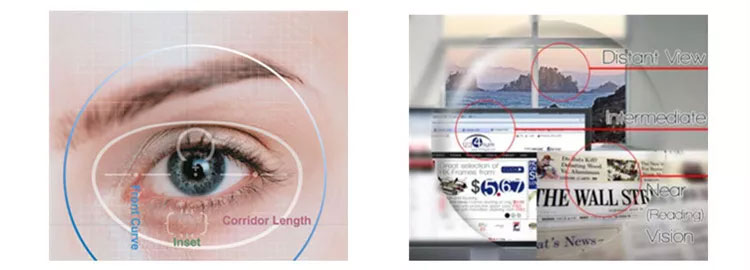

2. Features of Progressive Lenses

Progressive lenses address separate visual needs in one lens – usually with a "distance viewing" field build into the upper portion of the lens and a "near vision" field built into the lower portion. Rather than a line separating these areas, they are "blended" together, often with the middle portion of the lens serving as intermediate vision correction when necessary.

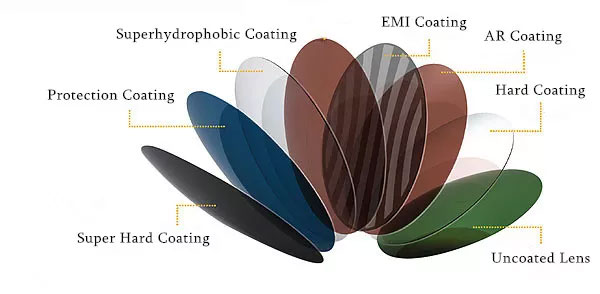

Coating Choice

| Hard Coating (HC) | Hard Multi Coating(HMC/ AR) | Super Hydrophobic Coating(SHMC) |

| To enhancethe hardness of the lens to prevent the substrate scratch | To protect the lens effectively from reflection | To make the lens waterproof, antistatic, anti slip and oil |

Technical Data

| POLYCARBONATE FINISHED PROGRESSIVE LENS TECHNICAL CHART | ||||||||

| Diameter (mm) | Base Curve(D) |

Sage @50mm(mm) |

Sage @40mm(mm) |

Center Thickness (mm) |

Edge Thickness (mm) | True Curve @1.530(D) | RXTrue Curve @1.530(D) | Back Curve (D) |

| 75MM | 2.75D | 1.73±0.01 | 1.12±0.01 | 10.6±0.15 | 12.5±1.15 | 2.75±0.05 | 2.90±0.05 | 4.25 |

| 4.75D | 2.85±0.01 | 0.84±0.01 | 12.5±0.15 | 10.5±1.15 | 4.75±0.05 | 4.81±0.05 | 4.25 | |

| 6.75D | 3.98±0.01 | 2.55±.001 | 9.5±0.15 | 8.1±0.15 | 6.75±0.05 | 7.0±0.05 | 6.25 | |

Products Show

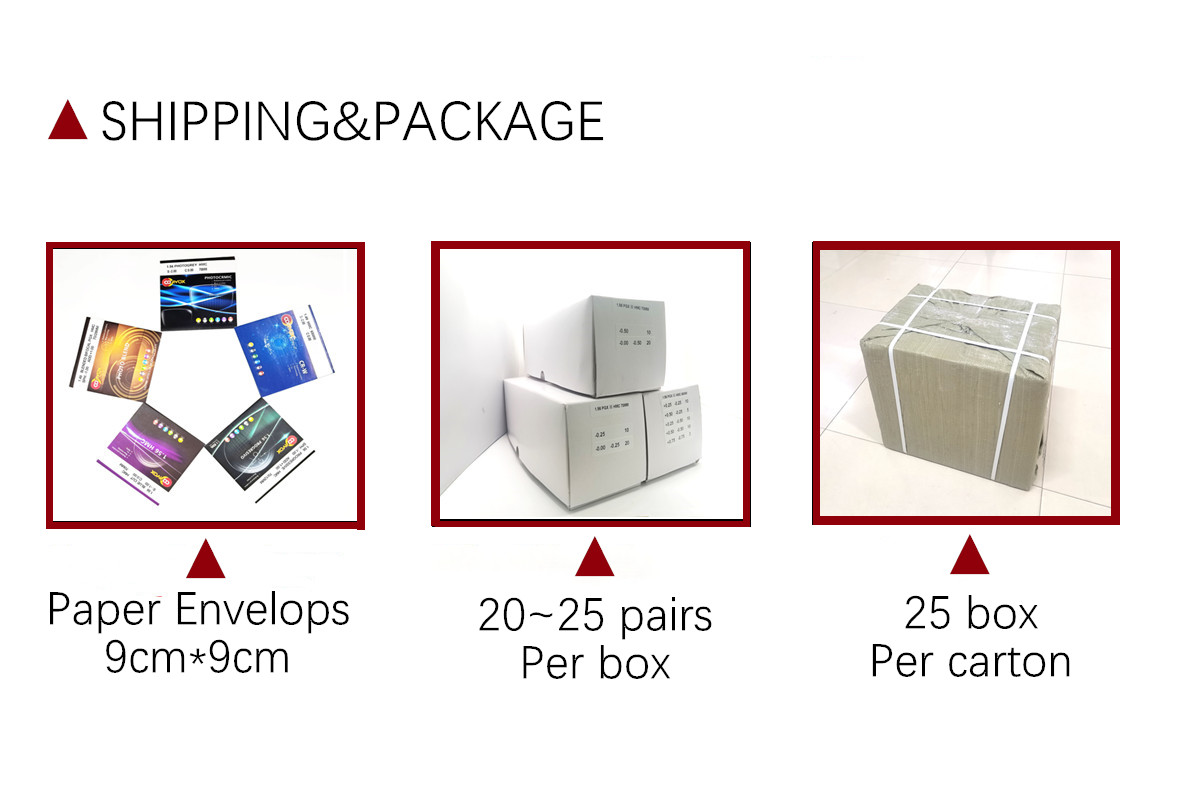

Product Packaging

- Packaging Details

1.56 hmc lens packing:

envelops packing (For choice):

1)standard white envelops

2)OEM with customer's LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

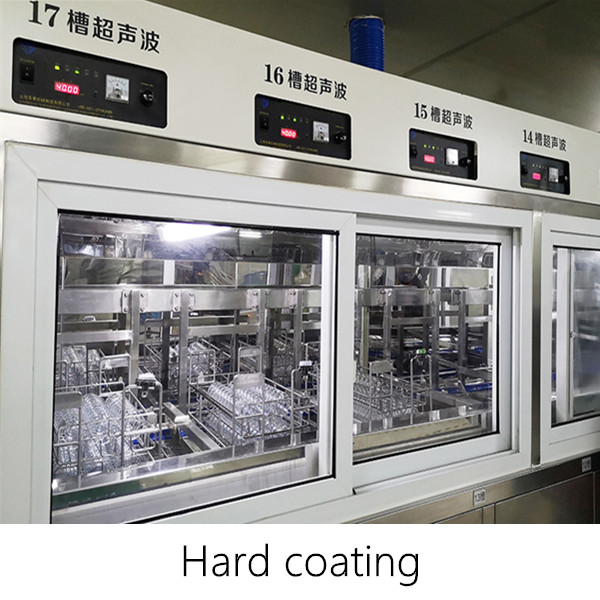

Production Flow Chart

About Us

Certificate

Exhibition

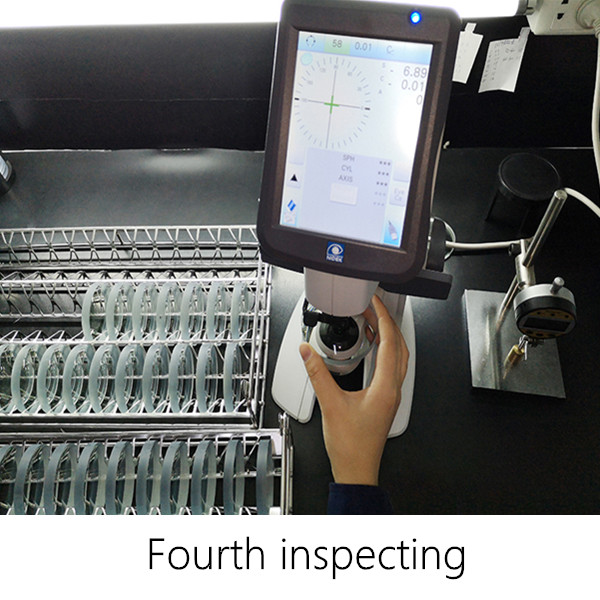

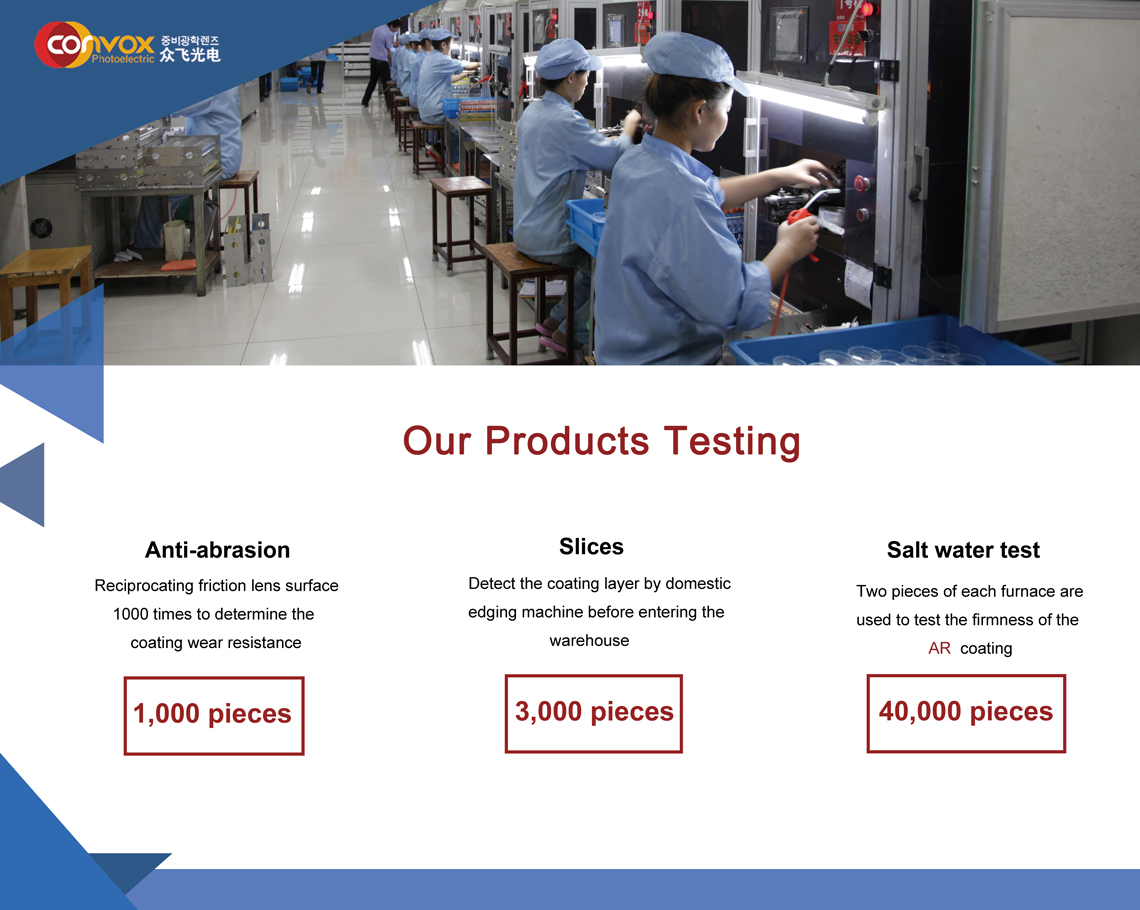

Our Products Testing

Quality Checking Procedure

FAQ