OEM Supply 1.74 Blue Cut Anti Blue Block Hmc Blue Coating Optical Lens

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for OEM Supply 1.74 Blue Cut Anti Blue Block Hmc Blue Coating Optical Lens, Teamwork is encouraged at all levels with regular campaigns. Our research crew experiments on various developments inside the industry for improvement in the merchandise.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for Photochromic and Anti Blue, Our company has already have pass the ISO standard and we are fully respect our customer ‘s patents and copyrights. If the customer provides their own designs, We are going to guarantee that they will be the only one can have that items. We hoping that with our good products can bring our customers a great fortune.

Description

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 PC | Lenses Material: | Resin |

| Lenses Color: | Clear | Coating: | EMI, HMC |

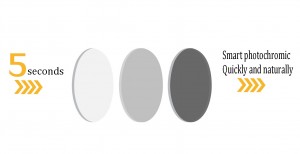

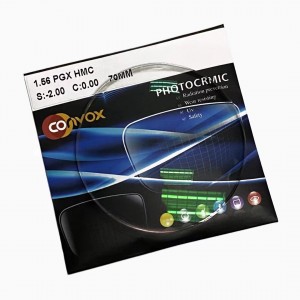

| Other Name | 1.59 PC POLYCARBONATE PHOTOCHROMIC PGX HMC | Product Name: | 1.59 PC POLYCARBONATE PHOTOCHROMIC PGX HMC |

| Material: | Acrylic | Design: | Aspheric |

| Multi color: | GREEN | Color: | Clear |

| Abrasion Resistance: | 6~8H | Transmittance: | 98~99% |

| Port: | Shanghai | HS CODE: | 90015099 |

What are polycarbonate lenses made of?

polycarbonate lens

A polycarbonate lens is made of a flexible plastic initially designed as a material for aerospace gear in the Apollo Space Shuttle expedition. Also known as poly, this lens is highly impact-resistant. It is famous for withstanding forces that typically chip or shatter other materials.

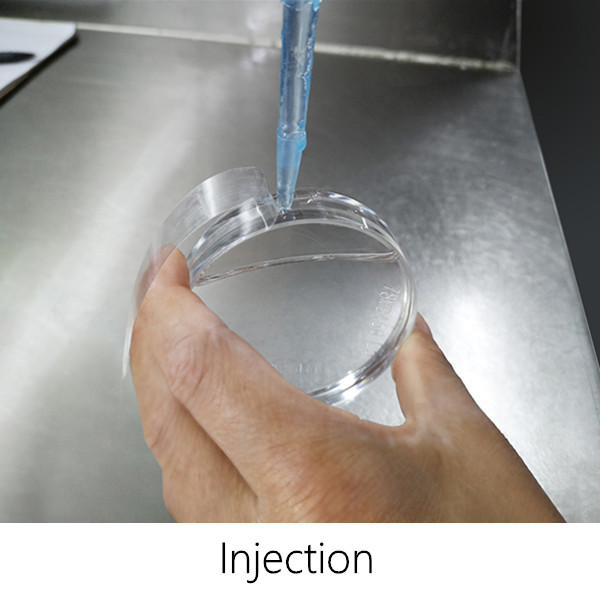

Polycarbonate is a super-strong material despite its lightweight quality. It is a thermoplastic that starts as a small and solid pellet, which undergoes injection molding. Poly is heated until it melts and is quickly poured into the lens mold. Then, it is compacted under high pressure and cooled off into the final lens form.

Advantages

Are polycarbonate lenses suitable for you?

How to Care for and Clean Polycarbonate Lenses

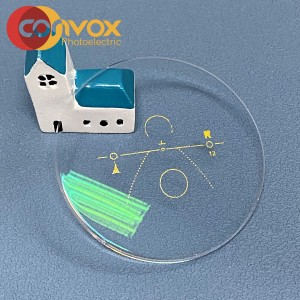

Detailed Images

Product Feature

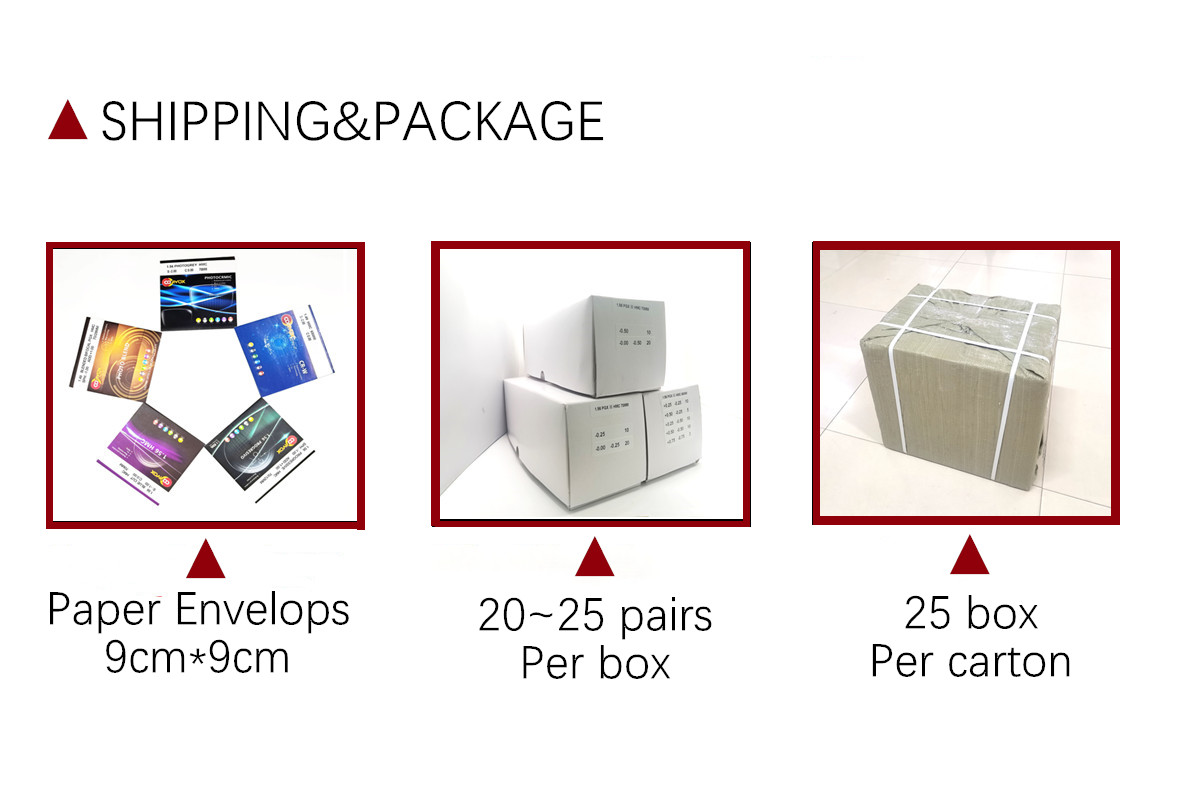

Product packaging

- Packaging Details1.56 hmc lens packing:envelops packing (For choice):

1)standard white envelops

2)OEM with customer’s LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

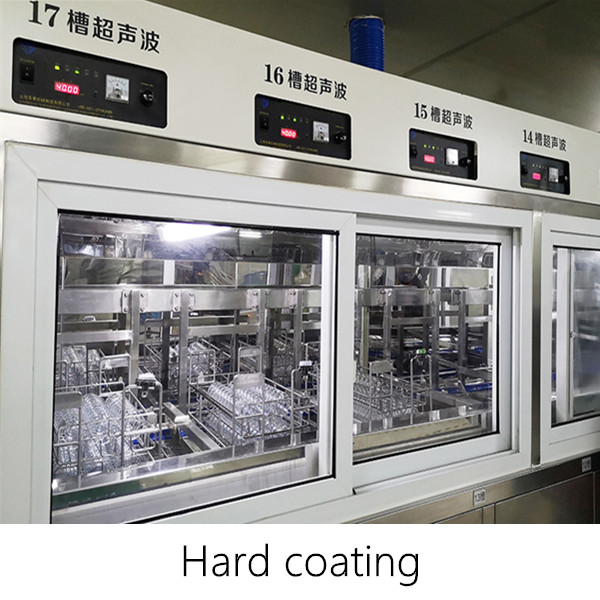

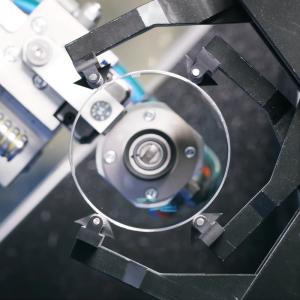

Production Flow Chart

About Us

Certificate

Exhibition

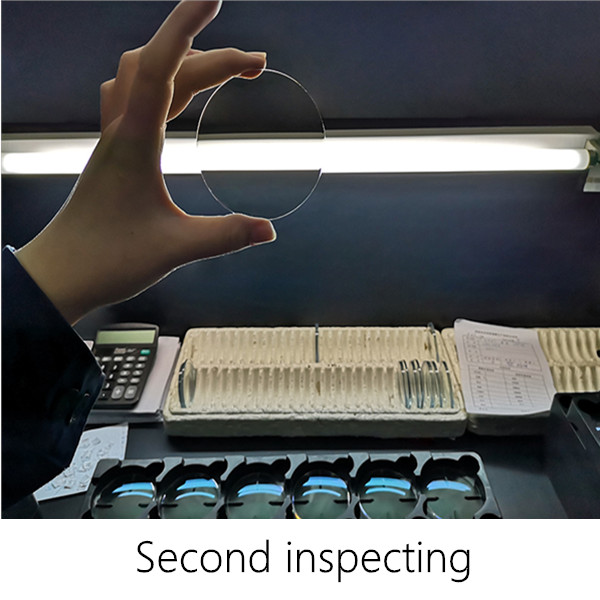

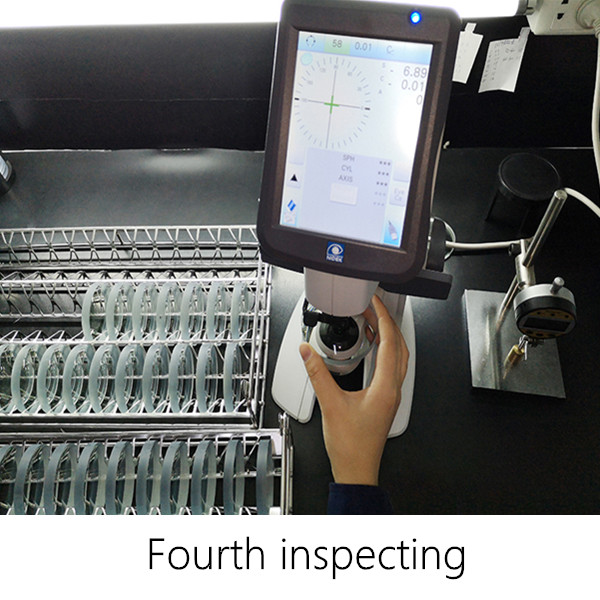

Our Products Testing

Quality Checking Procedure

FAQ

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for OEM Supply 1.74 Blue Cut Anti Blue Block Hmc Blue Coating Optical Lens, Teamwork is encouraged at all levels with regular campaigns. Our research crew experiments on various developments inside the industry for improvement in the merchandise.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for OEM Supply 1.74 Blue Cut Anti Blue Block Hmc Blue Coating Optical Lens, Teamwork is encouraged at all levels with regular campaigns. Our research crew experiments on various developments inside the industry for improvement in the merchandise.

OEM Supply Photochromic and Anti Blue, Our company has already have pass the ISO standard and we are fully respect our customer ‘s patents and copyrights. If the customer provides their own designs, We are going to guarantee that they will be the only one can have that items. We hoping that with our good products can bring our customers a great fortune.