Manufactur standard Prescription Blue Light Lenses - CONVOX 1.59 PC Polycarbonate HCT Hard Coating Tintable Optical Lens – CONVOX

Manufactur standard Prescription Blue Light Lenses - CONVOX 1.59 PC Polycarbonate HCT Hard Coating Tintable Optical Lens – CONVOX Detail:

What Products can we Produce?

Index: 1.499, 1.56,1.60, 1.67, 1.71,1.74, 1.76,1.59 PC Polycarbonate

1.Single Vision Lenses

2. Bifocal/Progressive lenses

3. Photochromic Lenses

4. Blue Cut Lenses

5. Sunglasses/Polarized lenses

6. Rx lenses for single vision, bifocal, freeform progressive

AR treatment: Anti-fog, Anti-Glare, Anti-virus, IR, AR coating color.

Quick Details

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 PC | Lenses Material: | Resin |

| Vision Effect: | Photochromic | Coating: | EMI, HMC |

| Lenses Color: | Clear | Product Name: | 1.59 PC POLYCARBONATE HCT |

| Other Name | 1.59 PC POLYCARBONATE HCT | Design: | Aspheric |

| Material: | Acrylic | Color: | Clear |

| Multi color: | GREEN | Transmittance: | 98~99% |

| Abrasion Resistance: | 6~8H | HS CODE: | 90015099 |

| Port: | Shanghai |

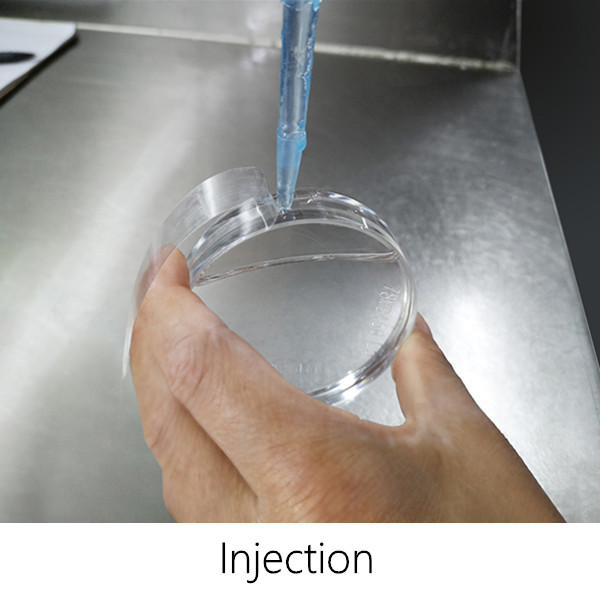

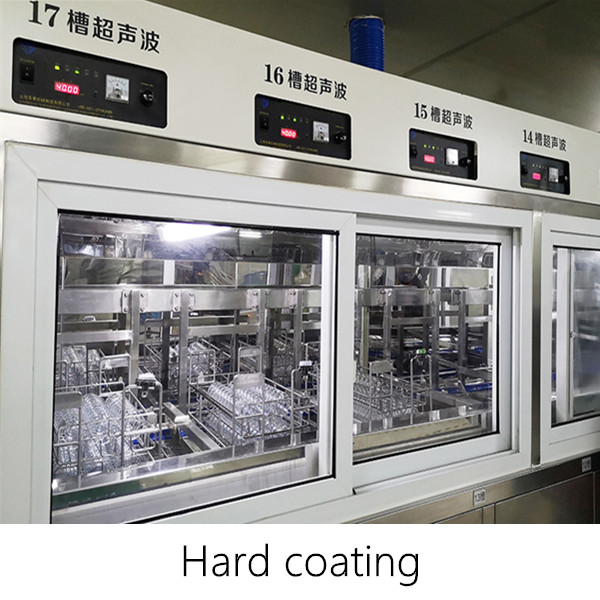

Production Flow Chart

Feature

More

—-Hardness: One of the best quality in hardness and toughness, high impact resistance.

—-Transmittance:One of the highest transmittance as compared with other index lenses.

—-ABBE: One of the highest ABBE value providing the most comfortable visual experience.

—-Consistency: One of the most reliable and consistent lens product physically and optically.

Description

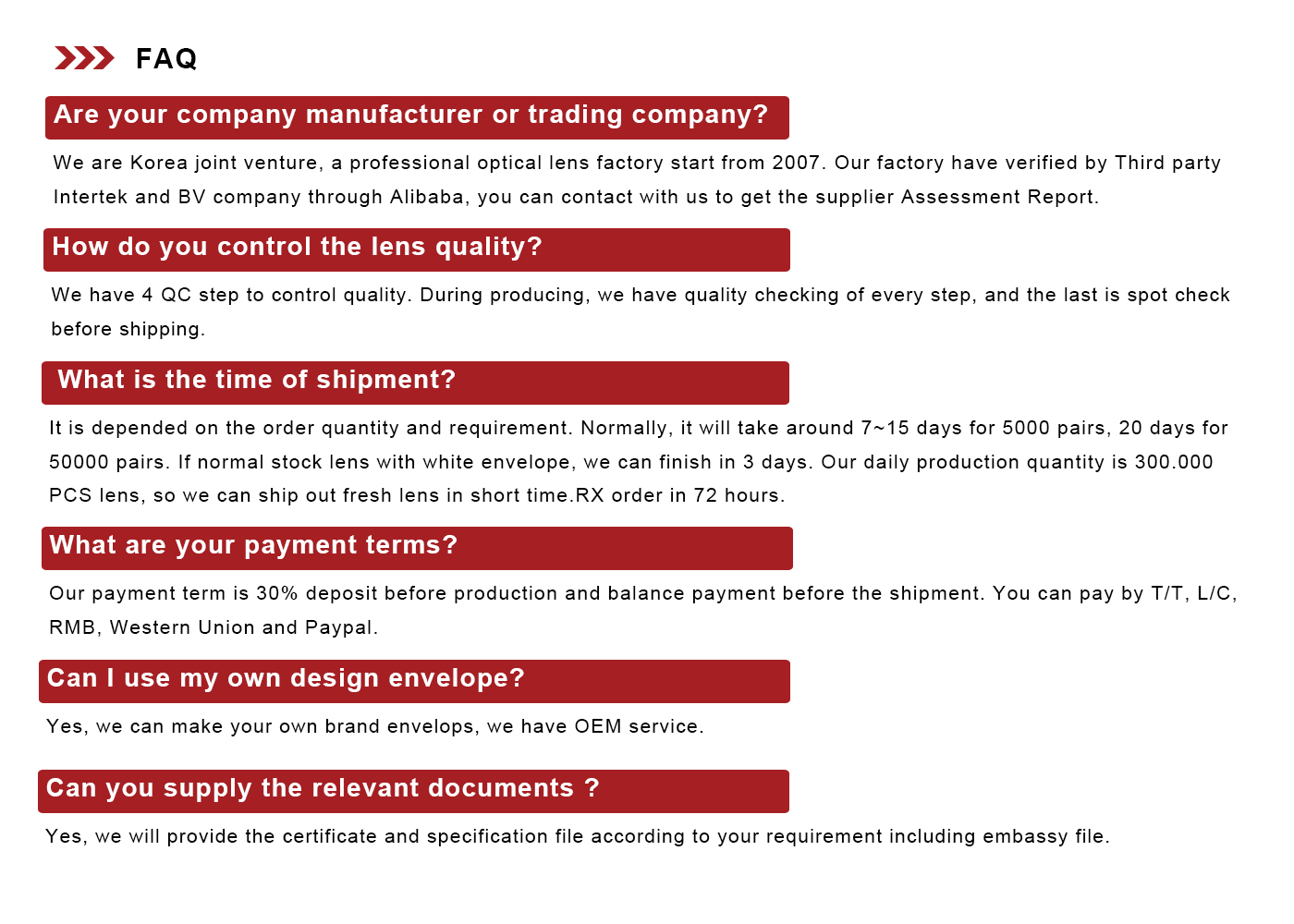

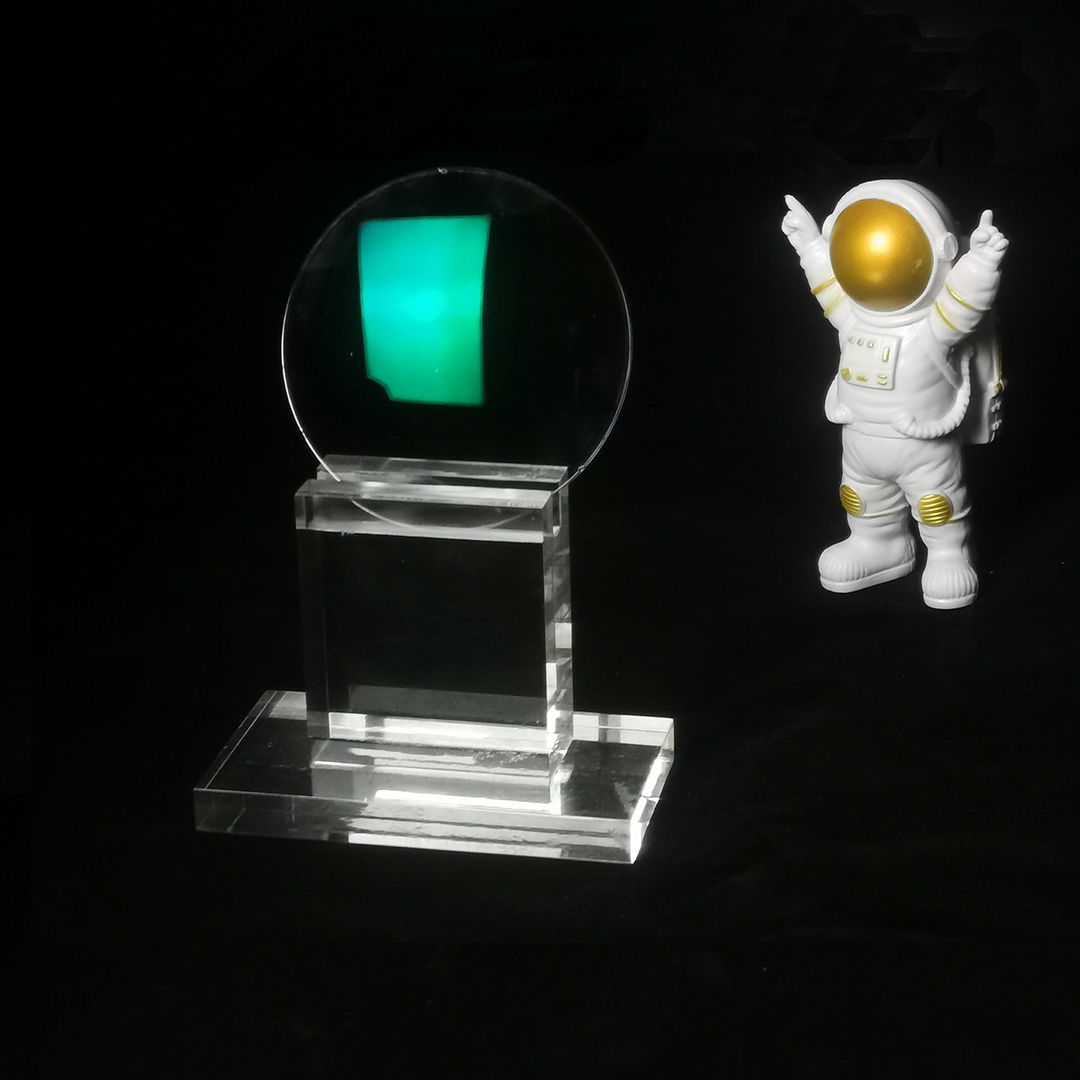

Polycarbonate was developed in the 1970s for aerospace applications, and is currently used for the helmet visors of astronauts and for space shuttle windshields. Eyeglass lenses made of polycarbonate were introduced in the early 1980s in response to a demand for lightweight, impact-resistant lenses.

Since then, polycarbonate lenses have become the standard for safety glasses, sports goggles and children’s eyewear. Because they are less likely to fracture than regular plastic lenses, polycarbonate lenses also are a good choice for rimless eyewear designs where the lenses are attached to the frame components with drill mountings.

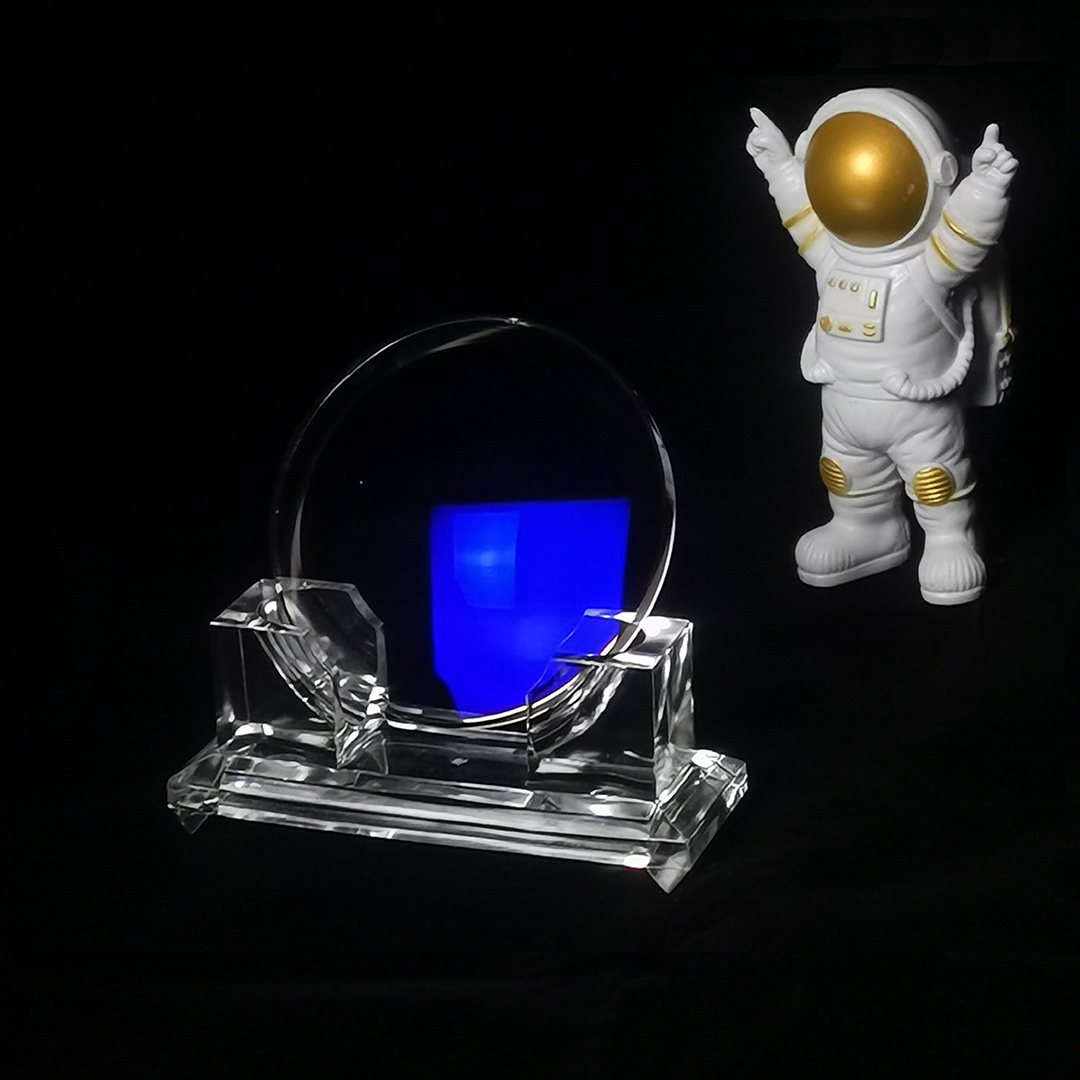

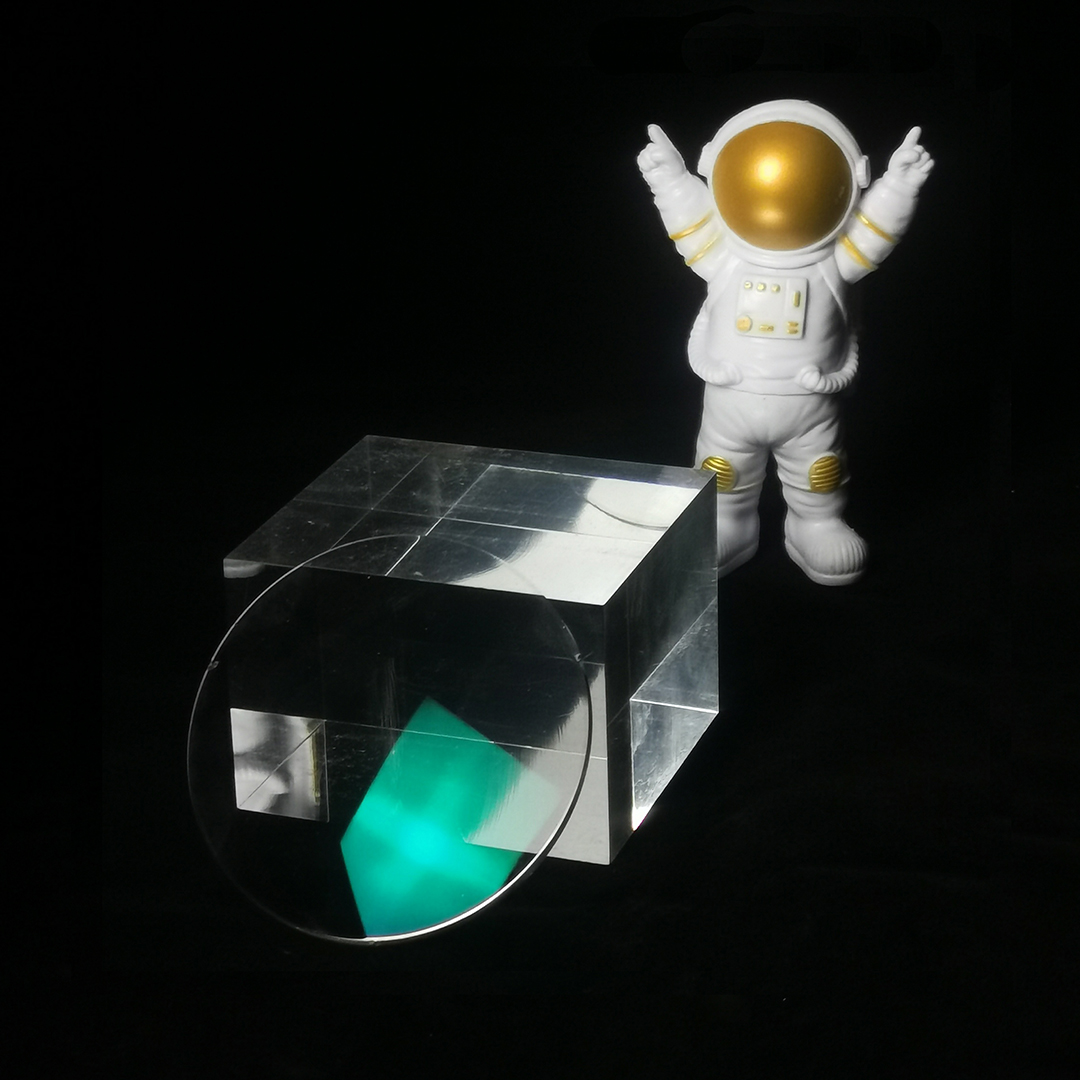

Products Show

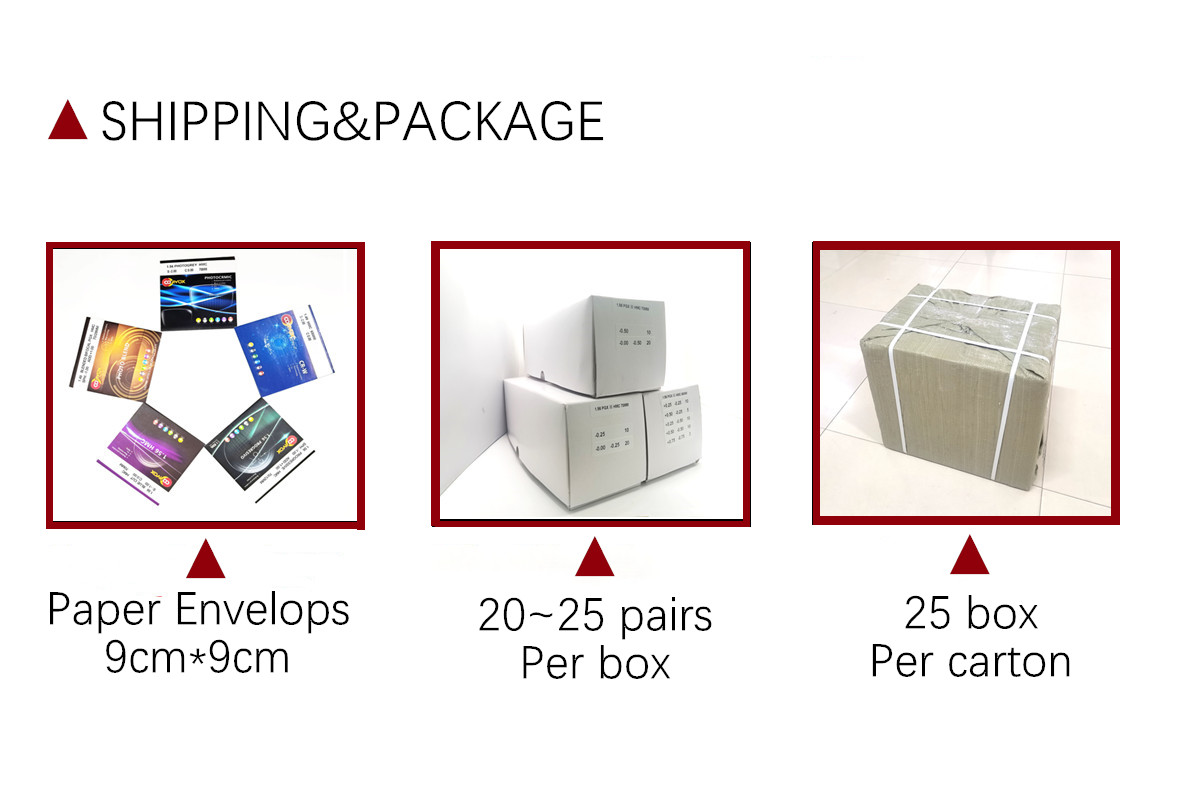

Product Packaging

- Packaging Details1.56 hmc lens packing:envelops packing (For choice):1)standard white envelops2)OEM with customer’s LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

Production Flow Chart

About Us

Certificate

Exhibition

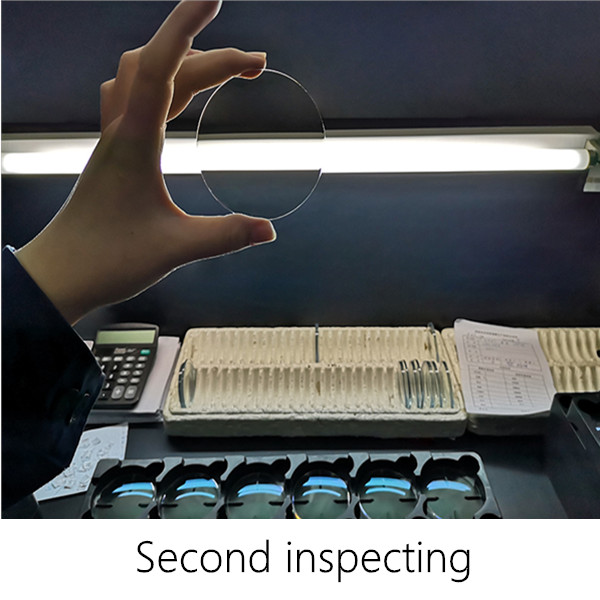

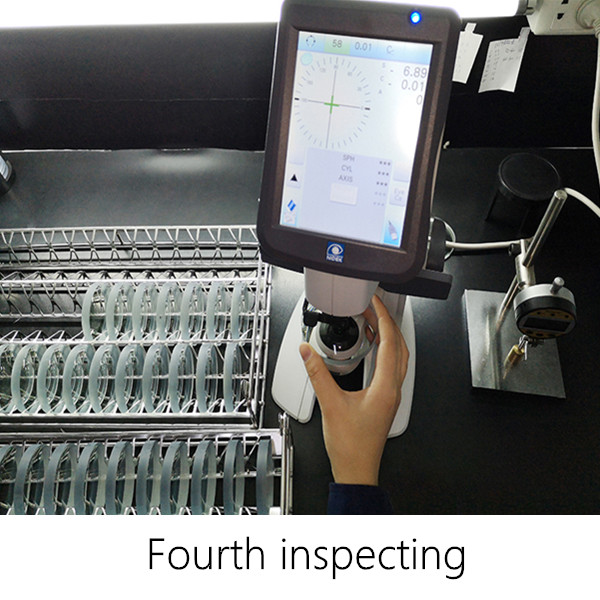

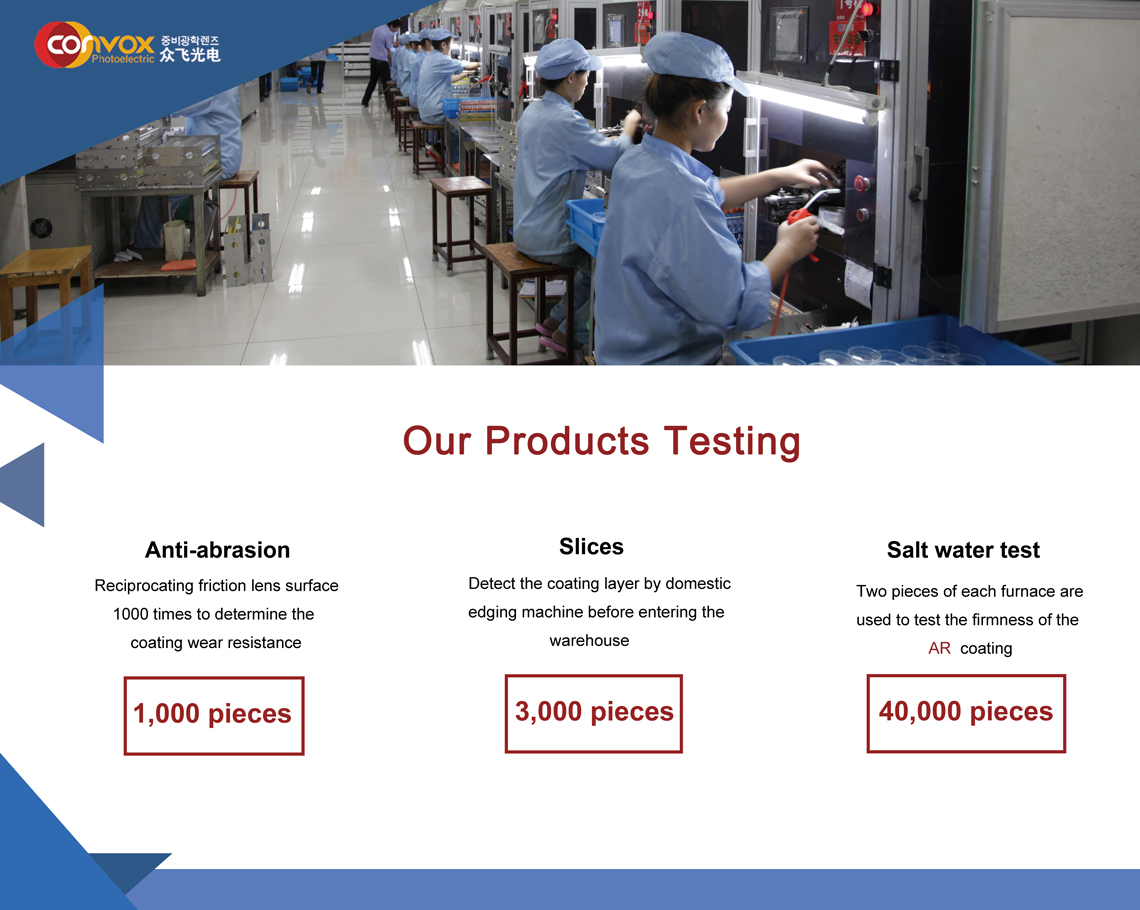

Our Products Testing

Quality Checking Procedure

FAQ

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Manufactur standard Prescription Blue Light Lenses - CONVOX 1.59 PC Polycarbonate HCT Hard Coating Tintable Optical Lens – CONVOX , The product will supply to all over the world, such as: Grenada, New Orleans, Jamaica, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly