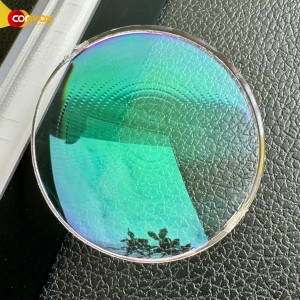

Convox Surfaced Freeform RX Lens

Top Design FreeForm

Convox RX Lens are unique, premium-quality products.

Your eyes are as unique as you are. With a pair of prescription lens from Convox you receive an equally unique, customised individual item. Lenses is one of decisive components of your spectacles, are specially adapted to you and your needs.

CONVOX TRANSTION LENS

(PhotoChromic lens )

OUR BEST LENS FOR EVERYDAY LIFE

The world's advanced color change technology,thecolor change(fading) is more uniform,faster,and the color change performance is excellent The lens surface have super hydrophobic AR treatment,easy to clean. Imported high-quality original raw materials which is more stable and high quality. Photochromic lenses that effectively block UV rays and aresuitable for all-day wear.

High-end Choice ----Real Transitions Gens and Xactive

(Provide Transitions Guarantee Card)

Production Advantages

Production Advantages

Distribution of spherical equivalent with steady methodology and steady plus methodology.

Rx:Plano Sph.+2.00

In a double-blind study

1. Wearers wore progressive glasses for a week. At no time did they know the type of lenses they were wearing.

2. All wearers were asked about their experience and level of satisfaction.

Scores of 4 and 5 on a scale of 0 to 5.

Inspired By Stability

Swim effect is a non-stable perception of the surroundings that causes discomfort, and reduces overall lens satisfaction, making adaptation more difficult, despite advancements made in progressive lenses, patients still experience swim effect. Lenses designed with Steady Methodology provide wearers with more stable and natural vision.

Past efforts to reduce swim effect in progressive lenses have primarilyfocused onthe reduction and precise placement of unwanted cylinder error in the lateral areasof the lens. However, unwanted mean poweralso plays a siqnificant role in the perception of swim effect, and inoverall wearer satisfaction, Mean power error candrastically increaseblur and reduce visual acuity.

More Function Choice

Applications

Our Service

➢ We will provide more precisely and efficiently manufacture and serve according to clients' prescription.

➢ We have professional QC team to ensure your product more better.

➢ Check the raw material before starting production.

➢ Have the random inspection during the processing.

➢ Make the 100% inspection before the shipments.

High Quality

Passed the ISO9001:2008 quality system authentication and ROHS authentication.

Our Advantage

We have Germany best RX machines for production even the 2025 new Model

Germany and Korea updated production technology supporting as Korean Joint venture

Production base is located in China, we get the Chinese Efficiency and offer customers good price

Use same material and processing machines as International big brand.

Providing similar FreeForm design as international brand, can match easy.

FAQ

Q: What warranty is offered for RX lens?

A: If our production problems we will redo for you as free.AR HMC quality will be around 2 years won't peel off under reasonable using.

Q:How can I make order?

A: We have online order web, you can contact with our sales team to open the RX account for you. Online web: http://rx-freeform.com

Q: How long I can get my order?

A:Our 95% orders’ production time are around 48 hours.

Some special treatment will take one or two days more.

Delivery time: DHL to Canada, USA and UK always take around 2-3 days.

Other area around 4-6 days depend on address.

Q: Can you do lens cutting/Assembling/ Remote cuting?

A:Yes, we can do the edging work if you can send us the frame or Remote file in OMA.

Q:Cancellation/RX changes

A:Order can’t be cancelled or changed once they have been placed in process. You can contact with service worker to check the situation firstly.

Q:Can you personalise lenses to my brand?

A:Yes, we can make customized envelope, Laser mark , fog mark and etc with extra charge.

Q:What are your payment methods?

A:We will confirm with you the order before production. You can pay order by Paypal, T/T, Western Union or Alipay and so on.

Q:How is your technical level?

A:Production machines: We have the best RX machines from Germany Loh and Schainder company .

production technology: We have Korean engineers available for technical support at any time.

Production software: Germany Optotech, USA IOT software provide the top design which can compare with international famous brand.

COMPANY PROFILE

Korean technology

Convox is Korea Joint venture, Adopt South Korea's toptechnologyon daily Lens production.

Excellent quality

All products areinspected through 5 Procedures, make sure every piece lens will bring you clear vision.

Personalizedcustomization

Advanced production equipment and 15+ years experiencesupport us can provide good service for Prescription order.

Timely supply

Modern storage systemand sufficient ready stockcan provide customers with fastdelivery service.

296

Eyewearlens type

9

Korean engineers

1168

Satisfied clients

48

Countries we sell

WHY CHOOSE US?

Korean technology support

Convox was invested and operated by Korea's top oplical equipment Manufaclurer.

The invest amount is up to $12 milion US dollers.

Over 15 years experience

Since 2007 our Chinese faclory started work, wo control the cost in a better way but according Korea produclion standard.

Full rangeof eyewear lens

We are specialized in manufacturing CR-39, 1.56, 1.59, 1.61, 1.67, 1.71, 1.74, 1.76 series of high quality resin lens.

Funclion lenses as PholoChromic, Blue block, Progressive, Anti-glare, Anti-fog and so on.

Personalized customized optimized lens

Our RX equipments are imported from Germany LOH company, can supply all kinds of special requirement include.

Freeform lens in 48 hours.

Technological innovation

Closely follow the market demand, develop producls and services leading the field of visual optics.